Page 5 - MetalForming February 2013

P. 5

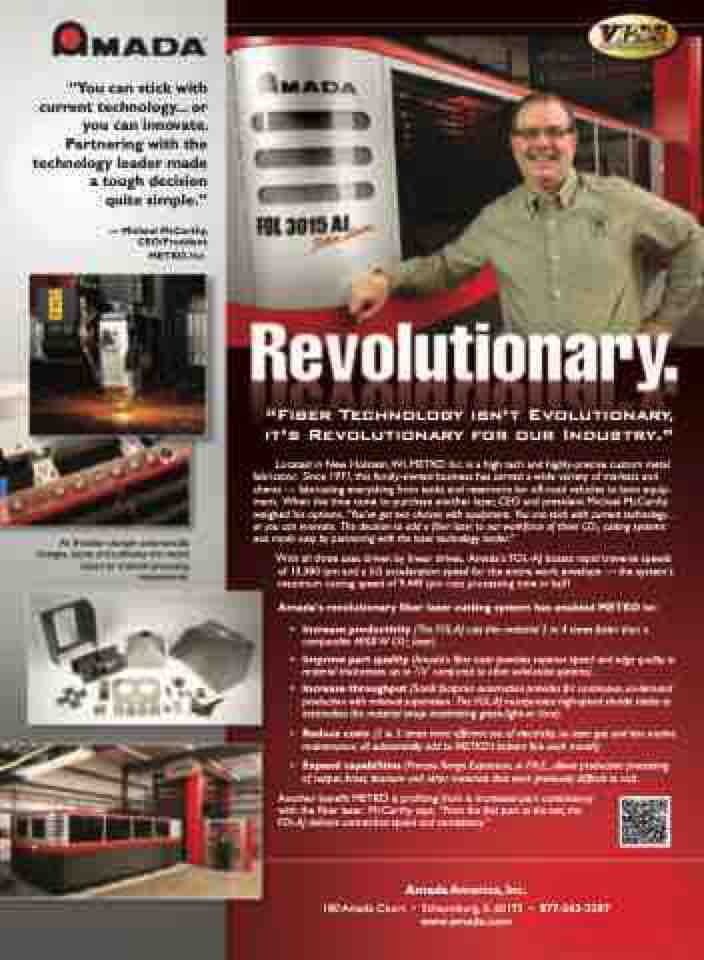

“You can stick with current technology... or you can innovate. Partnering with the technology leader made a tough decision quite simple.”

— Michael McCarthy, CEO/President

METKO, Inc.

An 8-station changer automatically changes, cleans and calibrates the nozzle based on material processing requirements.

“Fiber Technology isn’t Evolutionary, it’s Revolutionary for our Industry.”

Located in New Holstein, WI, METKO Inc. is a high tech and highly-precise custom metal fabricator. Since 1971, this family-owned business has served a wide variety of markets and clients — fabricating everything from tanks and reservoirs for off-road vehicles to lawn equip- ment. When the time came to purchase another laser, CEO and president Michael McCarthy weighed his options, “You’ve got two choices with equipment. You can stick with current technology... or you can innovate. The decision to add a fiber laser to our workforce of three CO2 cutting systems was made easy by partnering with the laser technology leader.”

With all three axes driven by linear drives, Amada’s FOL-AJ boasts rapid traverse speeds of 13,380 ipm and a 5G acceleration speed for the entire work envelope — the system’s maximum cutting speed of 9,449 ipm cuts processing time in half!

Amada’s revolutionary fiber laser cutting system has enabled METKO to: • Increaseproductivity(TheFOL-AJcutsthinmaterial2to4timesfasterthana

comparable 4000W CO2 laser).

• Improvepartquality(Amada’sfiberlaserprovidessuperiorspeedandedgequalityin material thicknesses up to 7/8˝ compared to other solid-state systems).

• Increasethroughput(Smallfootprintautomationprovidesforcontinuous,on-demand production with minimal supervision. The FOL-AJ incorporates high-speed shuttle tables to externalize the material setup maximizing green-light-on time).

• Reducecosts(2to3timesmoreefficientuseofelectricity,nolasergasandlessroutine maintenance, all substantially add to METKO’s bottom line each month).

• Expandcapabilities(ProcessRangeExpansion,orP.R.E.,allowsproductionprocessing of copper, brass, titanium and other materials that were previously difficult to cut).

Another benefit METKO is profiting from is increased part consistency with the fiber laser. McCarthy says, “From the first part to the last, the FOL-AJ delivers unmatched speed and consistency.”

Amada America, Inc.

180AmadaCourt • Schaumburg,IL60173 • 877-262-3287 www.amada.com