Page 46 - MetalForming February 2013

P. 46

FABTECH Draws Thousands to Vegas

Fiber Lasers Still Attracting Attention

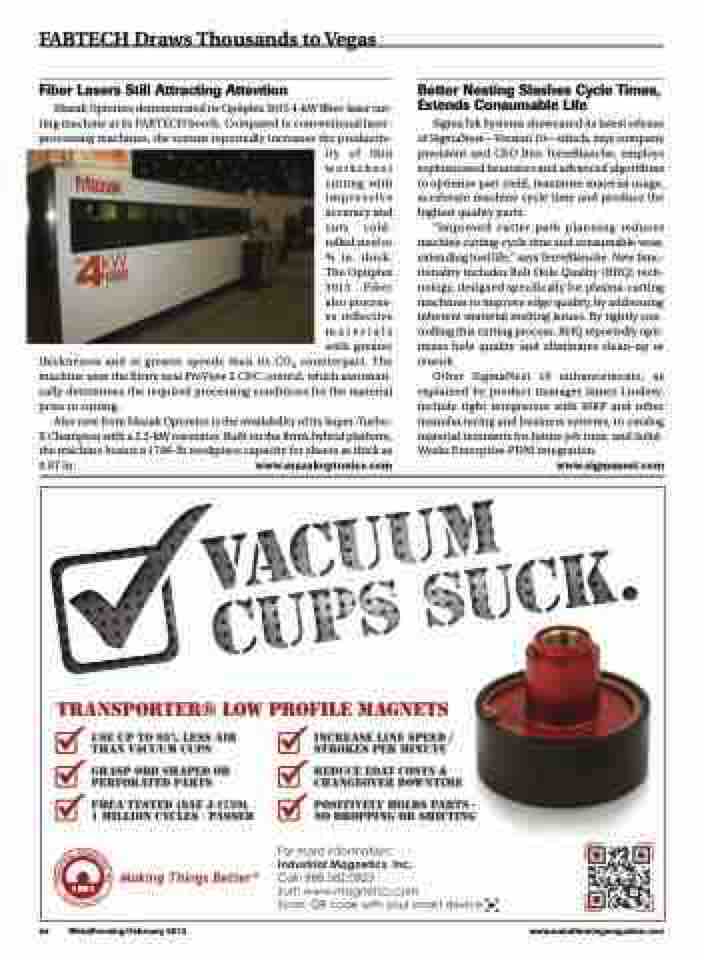

Mazak Optonics demonstrated its Optiplex 3015 4-kW fiber-laser cut- ting machine at its FABTECH booth. Compared to conventional laser- processing machines, the system reportedly increases the productiv-

ity of thin worksheet cutting with impressive accuracy and cuts cold- rolled steel to 3⁄4 in. thick. The Optiplex 3015 Fiber also process- es reflective materials with greater

thicknesses and at greater speeds than its CO2 counterpart. The machine uses the firm’s new PreView 2 CNC control, which automati- cally determines the required processing conditions for the material prior to cutting.

Also new from Mazak Optonics is the availability of its Super-Turbo- X Champion with a 2.5-kW resonator. Built on the firm’s hybrid platform, the machine boasts a 1786-lb.workpiece capacity for sheets as thick as 0.87 in. www.mazakoptonics.com

Better Nesting Slashes Cycle Times, Extends Consumable Life

SigmaTek Systems showcased its latest release of SigmaNest—Version 10—which, says company president and CEO Ben TerreBlanche, employs sophisticated heuristics and advanced algorithms to optimize part yield, maximize material usage, accelerate machine cycle time and produce the highest quality parts.

“Improved cutter-path planning reduces machine cutting-cycle time and consumable wear, extending tool life,” says TerreBlanche. New func- tionality includes Bolt Hole Quality (BHQ) tech- nology, designed specifically for plasma-cutting machines to improve edge quality, by addressing inherent material melting issues. By tightly con- trolling this cutting process, BHQ reportedly opti- mizes hole quality and eliminates clean-up or rework.

Other SigmaNest 10 enhancements, as explained by product manager James Lindsey, include tight integration with MRP and other manufacturing and business systems, to catalog material remnants for future job runs; and Solid- Works Enterprise PDM integration.

www.sigmanest.com

44 MetalForming/February 2013

www.metalformingmagazine.com