Optimal Weld Quality via Faster Cycle Time

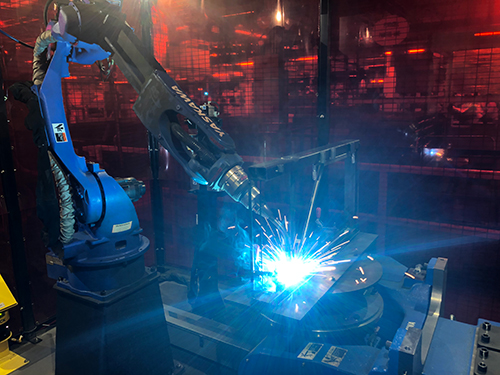

After a thorough process review, and a design and building phase, Freedman Seating implemented a custom robotic-welding workcell for the manufacture of foldaway seat frames.

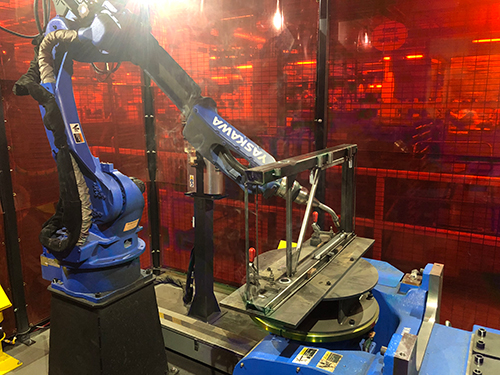

The solution featured a Yaskawa Motoman robot on a fabricated steel riser and an MA2010 extended-reach welding robot with through-the-arm torch cabling and a Miller Electric Continuum 350 metal-inert-gas weld package. The robot also features a ComArc seam-tracking package with 200V high-speed touch sensing function, suitable for tracking stainless-steel lap joints from 3-mm thick or more. This function assists in compensating for weld-joint location variance, helping the system produce precise, clean welds.

The custom tilt-rotate positioner combines a standard turntable base with framework to hold two MotoPos D500 tilt-rotate positioners on each side. Each servo-driven MotoPos D500 two-axis positioner has a 500-kg payload capacity with ±0.1-mm repetitive accuracy. Each can rotate ±370 deg. and tilt ±135 deg., enabling the continual welding of seat joints from 1⁄16 to 1⁄8 in. thick in continuous motion.

Coordinated motion software used in the robot controller ensures synchronized motion between the robot and positioners, with the robot and positioner axes moving in unison at an interpolated constant speed, allowing the torch to maintain optimum posture while the workpiece turns. This cohesion provides the ability to complete each safety critical weld in position—unlike the prior fabricating method—providing consistency in weld quality by always placing welds in the same location with programmed weld parameters.

A More Efficient Solution

After a successful run-through at Yaskawa Motoman headquarters, installation of the robotic workcell for the welding of seat frames began at Freedman. Within 2 weeks the system was up and running. Aiding the transition, two of Freedman Seating’s robot technicians attended Yaskawa Academy located at Yaskawa Motoman, where they learned the ins and outs of programming the robot and positioners in conjunction with coordinated motion.

Within 10 weeks of the run-through, the two technicians, along with technical experts from Yaskawa Motoman, had the system running at full capacity. Now Freedman is well on its way to achieving its return on investment within the designated 2.5-yr. payback period.

Since the workcell’s full implementation during the summer of 2018, the welding of foldaway seat frames with the new robotic system has become more efficient. Valuable time is no longer wasted by manually moving parts from station to station. Instead, the workcell’s arc welding robot, robust weld package, seam-tracking capabilities and tilt-rotate positioner work together to produce high-quality welds anticipated by customers in 7 min. or less per part for a 10-min. improvement.

The two-station system operates across two 8-hr. shifts, 5 days per week to maintain steady foldaway seat production. Instead of three robots and three human operators, the system requires just one human operator. In addition, the robotic welding workcell, with tilt-rotate positioner, has freed up the three robots to weld other parts and enabled the redeployment of two workers to other high-value operational tasks. MF

See also: Yaskawa America, Inc.

Technologies: Pressroom Automation, Welding and Joining

Video

Video