Aluminum and Stainless Steel

Aluminum parts—one-third the weight of comparable mild-steel stampings of the same thickness—make the material an attractive alternative for any mass-reduction effort. Many of the automotive alloys form much like steel with 100,000-psi yield strength, with half the stretching ability of steel. Because of its planar anisotropy and forming limits, successfully forming aluminum stampings depends highly on alloy, temper, blank shape and part design. Of prime importance: corner radii, draw depth, wall angle, steps and transitions. These interactive features combine to affect the cost and quality of aluminum stampings.

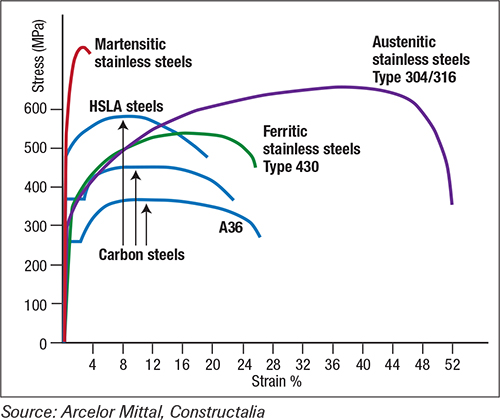

Many stainless-steel grades have workhardening rates much greater than those for mild steel, which leads many to believe that stainless steels are less formable than low-carbon grades. In reality, stainless steels are very formable (see accompanying figure), and many grades are substantially more ductile than mild steels. Some stainless steels can be deep-drawn into very complex shapes without the need for intermediate annealing, and even the less formable ferritic grades have outstanding ductility.

Aluminum and stainless steel, immediately after exposure to air, will form a thin natural oxide layer (aluminum or chromium oxide) on the sheet surface. This oxide layer can break down during forming and abrade forming and cutting tools. Even though the oxide layers are very thin, they significantly increase the level of friction between the tool and workpiece. This increase in friction and the resulting heat generated combine to rapidly degrade tool life. Higher wear rates increase costs for tool maintenance, downtime and production. Metalformers must select the proper processing methods, tool coatings and lubricants to optimize tool performance.

Blankholder Pressure and Die Clearance

Blankholder-pressure requirements for stainless steel will be much higher than those for low-carbon drawing steel. The ferritic grades (430) require about 50-percent more pressure, while austenitic grades (304, 316) may require as much as three times the applied force compared to forming low-carbon steel. Carefully consider this factor when evaluating energy and tonnage capacity during press selection.

Increased blankholder forces also are required for deep drawing aluminum stampings, since aluminum’s Young’s modulus is one-third that of steel. This reduction in Young’s modulus increases the likelihood of wrinkling, oil canning and surface distortion, while also increasing the magnitude of springback by a factor of three compared to steel sheet of equivalent yield strength.

Also, the required clearances between the draw post and die cavity will be greater for stainless steels compared to mild steels. Austenitic grades require a clearance equal to the workpiece thickness plus an additional 35 to 40 percent per side; most ferritic alloys require workpiece thickness plus 10 to 15 percent additional clearance per side.

New Conference Brings Clarity

If you or your company designs dies or produces stampings from a variety of different material types, it can be difficult and time consuming to find the resources and technical information needed to solve these ever-changing challenges. To help make life easier, PMA has developed a new annual conference that specifically addresses the needs of metal stampers and their tool-and-die suppliers.

PMA’s first annual Metal Stamping Technology and Tool & Die Conference will be held in Chicago, IL, December 5-6, 2016. Presenters will address the latest technologies developed for processing metal stampings from mild and high-strength steels, stainless steels and aluminum alloys. Topics include die design and construction, tooling, lubrication, presses and press-line equipment. Conference sessions also include two keynote presentations: Industry Benchmarking: Current Trends in the Metal Stamping and Tool & Die Industries; and Why Metal Fabricators Should be Paying Attention to the Internet of Things (IoT) and Industry 4.0.

Individual technical tracks are available, including: stainless steel 101, design guidelines for stamping aluminum, transfer-press die simulation, sensor technology for progressive dies, lightweight stamping technologies, tooling solutions for AHSS, new technology for measuring lubricant thickness, incremental microplastic forming for low-volume metalforming, and scanning and surface morphing solutions for die design and reverse engineering. And, tabletop exhibits will feature several industry-leading suppliers.

To learn more, contact Marianne Sichi, PMA technical programming manager; msichi@pma.org. MF

Industry-Related Terms: Forming,

Layer,

Oil Canning,

Ram,

Stainless Steel,

Stroke,

Surface,

Thickness,

Wrinkling,

Alloys,

Blank,

Blanking,

Corner,

Die,

Draw,

Drawing,

Ferritic,

FormView Glossary of Metalforming Terms Technologies: Tooling

Peter Ulintz

Peter Ulintz Stamping high-tensile-strength materials can easily push press-line performance requirements well beyond the capabilities for which the equipment was originally designed. Stamping such materials can affect the size, strength, power and overall configuration of every major component of the press line, including coil-handling equipment, lubrication systems, presses and tooling.

Stamping high-tensile-strength materials can easily push press-line performance requirements well beyond the capabilities for which the equipment was originally designed. Stamping such materials can affect the size, strength, power and overall configuration of every major component of the press line, including coil-handling equipment, lubrication systems, presses and tooling.