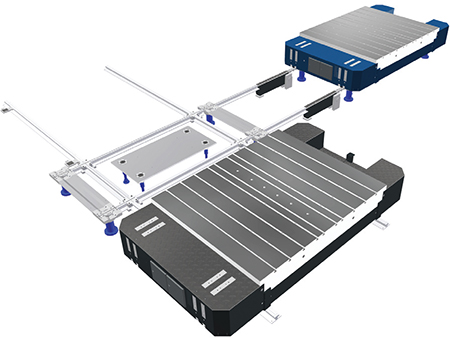

Heavyweight Moving Bolster for AP&T Presses

January 1, 2019Comments

AP&T has introduced a new version of its Moving Bolster for rapid and safe tool changes on tools weighing 30 mtons and more. The bolster, for AP&T’s newly manufactured presses, offers a greater degree of freedom as compared to conventional surface tables, according to company officials.

AP&T has introduced a new version of its Moving Bolster for rapid and safe tool changes on tools weighing 30 mtons and more. The bolster, for AP&T’s newly manufactured presses, offers a greater degree of freedom as compared to conventional surface tables, according to company officials.

“First and foremost, the solution is very flexible,” says Michael Karlsson, manager of development for press products. “The bolster can be conveyed in and out of the press in any direction, which means it can be adapted to suit the conditions at the individual factory as well as enable quick changes. And, its drive, entirely electric, results in robust and precise control. It also enables execution of the entire tool change using a few easy clicks of a button—an important advantage for customers with a highly automated process.”

Safety has been emphasized in this new version, with an optical scanner on the bolster continuously registering conditions in front of the bolster, and communicating those with the control system. The scanner can be programmed to divide the area in the direction of motion into an outer and an inner safety zone. If the scanner detects a person or an object in the outer zone, bolster speed automatically reduces, and stops completely should a person or an object be discovered in the inner zone.

See also: AP&T North America Inc.

Technologies: Stamping Presses, Tooling

Video

Video