Hexagon, Raytheon Technologies Develop AM-Build Simulation Software

November 1, 2022Comments

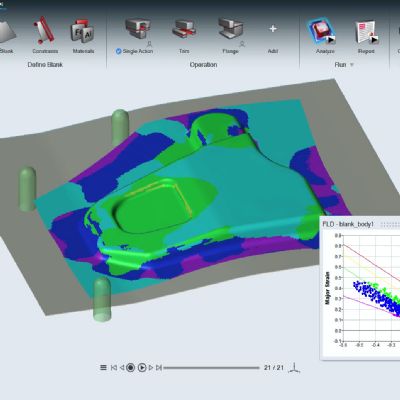

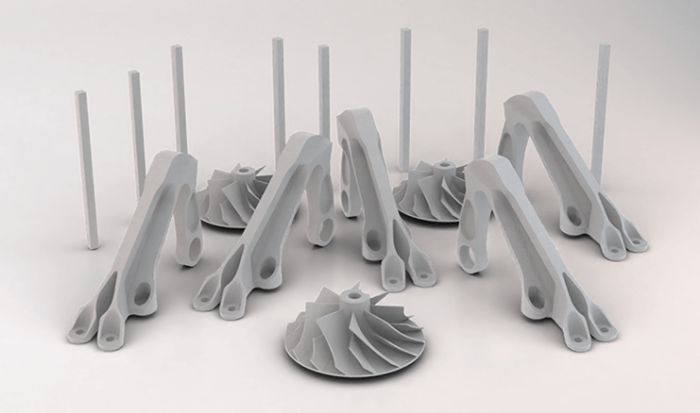

A simulation tool for evaluation and optimization of metal-additive manufacturing (AM) processes through the prediction of thermal history and defects at the laser-path and powder-layer scale has been developed by Hexagon’s Manufacturing Intelligence division and Raytheon Technologies’ Pratt and Whitney business. The new software will predict defects before the expensive and time-consuming printing process begins, with this analysis helping designers and engineers evaluate the print outcome and test combinations of materials, geometries and print processes.

A simulation tool for evaluation and optimization of metal-additive manufacturing (AM) processes through the prediction of thermal history and defects at the laser-path and powder-layer scale has been developed by Hexagon’s Manufacturing Intelligence division and Raytheon Technologies’ Pratt and Whitney business. The new software will predict defects before the expensive and time-consuming printing process begins, with this analysis helping designers and engineers evaluate the print outcome and test combinations of materials, geometries and print processes.

The software, to be made available to companies engaged in AM and complementary to Hexagon’s existing Simufact Additive tool, offers similarity to the existing Simufact Additive user interface. This allows simple integration into existing manufacturing processes by users without the need for extensive training, according to Hexagon officials.

“We have partnered with Raytheon Technologies to deliver an intuitive and accessible tool that will help engineers quickly predict and mitigate risks,” says Jeff Robertson, Hexagon’s director of global business development. “The ability to evaluate full laser powder-bed fusion parts on the mesoscale will reduce the effort to achieve part certification and thereby support industrialization of metal 3D printing.”

See also: Hexagon Manufacturing Intelligence

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementMetalForming LIVE: On the Shop Floor

Wednesday, April 24, 2024

Event

Event  Pressroom Automation

Pressroom AutomationMetalForming LIVE On the Shop Floor 2024: Part 1 Re...

Wednesday, April 24, 2024

Webinar

Webinar