Light Curtains, Noncontact Buttons Protect Assembly Operators

October 1, 2008Comments

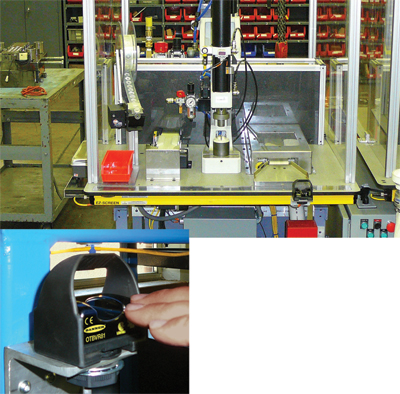

At Buhrke Industries, Arlington Heights, IL, concern for safety is illustrated by the production method used to assemble automotive airbag components. An operator loads a part onto the assembly machine and places his hand on a noncontact optical touch button to initiate the cycle, which then runs automatically. The optical touch button, from Banner Engineering Corp., Minneapolis, MN, is designed so that the operator must keep his hand on the button until the press shuts and the pinch point is closed.

|

Although this method minimizes risk to the specific machine operator should his hand be placed in the equipment during a cycle, precautions also are taken to prevent injury to additional Buhrke personnel working in close proximity. To protect these workers, as well as improve workflow, Buhrke uses Banner’s Ez-Screen safety light screen.

The light screens guard points of operation, access areas and perimeters. These noncontact systems protect fingers, hands and ankles by detecting the presence of opaque objects that interrupt a part of the predefined area. The light screen sends a safety stop signal to the controls of the machine, which react immediately to stop the hazardous motion before an incident occurs.

Plus, Banner’s Ez-Screen safety light screen offers versatile mounting options for flexible use, without interfering with normal production processes.