Intricate Parts Show Capability of Velo3D AM Systems and Software

October 14, 2021Comments

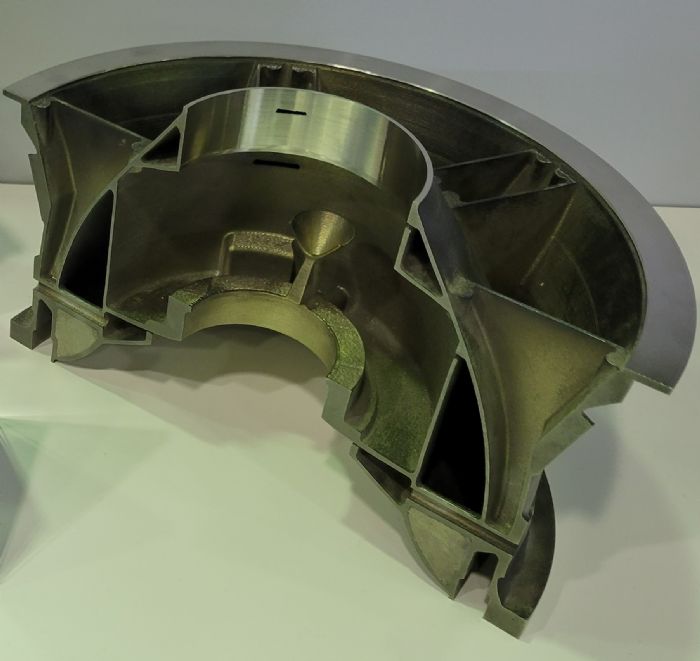

At RAPID +TCT…Velo3D displayed a roster of intricate parts produced via its Sapphire series of metal laser powder-bed printers, backed by the company’s Flow pre-print software and Assure quality-control software. Parts shown included this cutaway of a gas-turbine diffuser, printed with Inconel 718 for Siemens Energy. Redesigning for additive manufacturing (AM) resulted in reduction of 61 parts to one.

At RAPID +TCT…Velo3D displayed a roster of intricate parts produced via its Sapphire series of metal laser powder-bed printers, backed by the company’s Flow pre-print software and Assure quality-control software. Parts shown included this cutaway of a gas-turbine diffuser, printed with Inconel 718 for Siemens Energy. Redesigning for additive manufacturing (AM) resulted in reduction of 61 parts to one.

The company is beginning delivery of its newest system, the eight-laser Sapphire XC large-format 3D metal printer, by year’s end. It reportedly can increase production throughput by five times and reduce cost-per-part by as much as 75 percent as compared to the standard Sapphire system.

Sapphire XC features a build volume of 600-mm dia. by 550 mm height, as compared to 315-mm dia. by 400 mm height in the Sapphire, and employs eight 1000-W lasers, as compared to two 1000-W lasers in the Sapphire. It utilizes the same optical-train design, recoater technology, gas-flow technology and metrology as the current Sapphire and is fully integrated with Velo3D’s Flow pre-print software and Assure quality-control software.

Qualified material alloys compatible with the Sapphire XC include aluminum F357, titanium 6AI-4V, Inconel 718 and Hastelloy X.

See also: Velo3D

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingAI in Manufacturing Makes Impressions at INTECH

Wednesday, April 17, 2024

AP&T Collaborating with ArcelorMittal for Press Hardening Ap...

Wednesday, April 17, 2024

Materials

MaterialsSteel Warehouse Rebrands its Cold Mill Division, Invests in ...

Tuesday, April 16, 2024

Pressroom Automation

Pressroom AutomationProducing the New Aluminum-Intensive Porsche Taycan: Touring...

Monday, April 15, 2024

Video

Video