Assessments Determine a Starting Point

The generations of employees of Oberg Industries are the true legacy and backbone of the company’s years of success, according to company officials. Maintaining these people and getting newcomers interested in pursuing careers in manufacturing are no easy tasks, and Oberg Industries goes to great lengths in such efforts.

For example, the company actively recruits new employees, and also encourages personnel to become involved in industry initiatives and community activities to promote manufacturing. For example, Greg Chambers, Oberg director of corporate compliance, is a long-standing member and current chairman of the National Institute of Metalworking Skills (NIMS), leading the to establish national performance standards. Chambers recently was appointed to the Advisory Committee for the U.S. Dept. of Labor on apprenticeships and is co-chairman of the precision machining technology competition of the National- Skills USA program. He has also served as the past president of the American Apprenticeship Round Table.

Dave Crawford, Oberg human resources manager, champions the cause for talent acquisition, regularly seeking hard-to-find CNC specialists and machinists with the right skill sets. Unique about Crawford’s approach, he lobbies the marketplace, visiting more than 80 schools annually, serving on five advisory boards and participating in the PA Center of Advanced Manufacturing - State Initiative and the PA-Skills USA. Crawford’s leadership champions the cause to place Oberg’s name out there, and promotes the manufacturing industry to the academia leadership that regularly counsels America’s youth on career issues.

Neil Ashbaugh, Oberg senior market support specialist, has collaborated with the company’s human resources department to promote branding of the business to potential employees through his involvement with the Butler County, PA, Manufacturing Consortium and through his work with county and state economic development agencies as well as with elected officials. His goal: Positively influence people, families, and businesses to uplift manufacturing business causes and the potential for local jobs.

Not a one-size-fits-all operation, Oberg’s apprenticeship program is dictated by the assessed skills of the employee and the requirements of a particular job. Off the bat, within one year new apprentices complete more than 90 online classes, on company time. This helps assess the self-starting nature of employees.

“We have found that self-motivated employees who quickly complete the online classes shine on the shop floor,” says Chambers, “whereas those without much enthusiasm or who seem tentative about online training tend to struggle on the shop floor.”

Shop-floor and other training follows, with an apprentice coordinator assigned to each job area. The coordinator interacts with apprentices daily, ensuring they complete their weekly apprenticeship tasks.

“Formally, we evaluate apprentices every six months,” says Lou Proviano, director of human resources. “If they do well, they receive a pay bump and we keep moving them across the competency line.”

Besides the pay increases and satisfaction of earning journeyworker status, apprenticeship graduates become eligible to receive third-party credentials that follow them throughout their careers, inside and outside of Oberg.

Solid Wages and Benefits Attract, Keep Talent

|

| “Being responsible for a quick-turnaround department, cross-training provides me with versatile employees,” says Tim Wiles, production supervisor and 30-yr. employee who started with the company as an apprentice. “I’ve received a lot of training for leadership and for dealing with people, to prepare me for supervision. There are a lot of good mentors in this company.” |

The apprentice pay and skills bumps are part of an overall solid employee-benefit mix that allows Oberg to attract and retain talent in a competitive region. Starting wages for production employees average 20 percent higher than most other local companies in the metalforming industry, according to Oberg officials, and the company regularly benchmarks for competitive pay and benefits packages. Importantly, due to business demands, for more than 30 yr. Oberg has provided more employees the option of working 50 hr./week or more, typically in 10-hr., five-day shifts. The added hours certainly put more money in employees’ pockets.

“This provides 20 hr. of overtime at 1.5 times the employee’s hourly rate every two weeks,” explains Proviano. “The result is almost 38 percent more in the paycheck of the average machinist, machine operator, toolmaker, press operator, mechanic and apprentice. This overtime model has been part of the fabric at Oberg for many years, where our employees have touted some of the largest W2’s in the valley in our industry. While smaller shops use the overtime tool as the exception to managing business demand, we use it as the Oberg standard. And in recent years, we’ve even offered flexible work schedules, allowing for a range of start-finish times to allow employees to better balance work and home life.”

Oberg also provides merit reviews for wage increases, and offers shift-pay differentials of as much as 20 percent plus additional incentives for lead personnel. In addition, the company offers an annual bonus program based on profitability that has provided additional employee income. On average, Oberg offers merit raises of 2 to 3 percent, coupled with bonus payouts of 2 to 3 percent. In 2011, the company delivered a 2 percent merit pay program and paid bonuses of 3.34 percent. These bonuses are paid on all earnings, including the company’s standard overtime (where a 50-hour work week is normal), shift differentials and other premiums. Thanksgiving gifts and Christmas bonuses, special vacation-accrual incentive depending on the average hours worked all year, a frozen defined-benefit retirement plan, ESOP retirement plan and matching 401(k) plan are other perks. Employees are recognized through a service-awards program as well as merit and values awards.

Software Streamlines Training

Recently purchased software provides recordkeeping for training, allowing Oberg to track training and assignments related to the firm’s various aerospace, medical and other certifications.

|

| “I really like the alternate work schedule,” says toolmaker Bill Hewitt. “We can start at different times as long as we work 10-hr. days and our schedules don’t conflict with machine operations on the next shift. I work from 5 a.m. to 3 p.m., which allows me to spend more time with my family.” |

“In 2011, we added the AS9100 Rev.C aerospace certification as well as the ISO 1345 medical certification,” says Dave Rugaber, Oberg executive vice president, sales and marketing. “These certifications, above and beyond what we typically do for our typical ISO standards, required additional training documentation.”

|

| “In our industry, it’s hard to find good people and keep them,” says purchasing manager Eric Johnson. “Taking the time for training shows that the company cares.” |

“With the software,” adds Proviano, “we are more diligent and getting better at keeping tabs on the competencies and skill sets in the organization.”

A better handle on training, resulting from the sotware, enables Oberg to tailor its training programs and avoid time- and money-wasting instruction that may be repetitive or inconsequential.

Technology Investment Spurs Hiring, Training

|

| “I came here wanting to learn and didn’t want a dead-end job,” explains quality inspector Nancy Macurdy. “I went through the apprentice journeyworker training, and kept telling my boss that I wanted to learn more. Here, if you have the desire to learn and a positive work ethic, you can take the career path that you want to. The pay is good, and Oberg has provided me with a good job and family balance.” |

The company recently held a career open house to find experienced talent or potential employees with the aptitude and drive necessary to enter the apprenticeship program. New hires are needed to run metalforming and machining equipment that Oberg consistently adds to its stable. Over the past 3 yr., the company has invested more than $10 million in capital equipment, including milling, turning, and multiaxis machining centers as well as stamping presses and EDM equipment. While many industrial companies held back on equipment investment while riding out economic uncertainty, the unique level of capital spending by Oberg over this period represents a commitment to employees and shareholders that the company is in business for the long haul. Of course, adding new equipment means preparing employees to run it.

“To operate such advanced equipment, we are hiring more seasoned people,” says Chambers, “and we are using the National Institute for Metalworking Skills (NIMS) performance standards to assess them and learn how we can augment their skills with our own training programs.”

|

| “Another deaf person was working here, so I was interested,” explains wire-EDM operator Scott Craig, who went through a 4-yr. apprenticeship and has worked for Oberg for 15 yr. “I work on three machines alone, or sometimes partner to work on five. This job is a lot of fun. I have to think every day, but the time goes very quickly.” |

Oberg has tweaked its training programs to match the requirements of operating its newest and most sophisticated equipment, says Wagner.

“As we populate the floor with new equipment,” he says, “we see a need to have a short-term training mission or platform in tandem with the longer-term apprentice program. So we might hire someone with minimal experience but who can learn how to run that machine with the notion that they will be productive one week after they get here. So we will train for that, but the training does not end there. These personnel then will enter our formal long-term training programs.”

Company-wide, including non-U.S. operations in Costa Rica and Mexico, Oberg’s employee base has risen by 11 percent since 2009 to a total of 728 employees. In 2011, the firm added 40 employees and is looking to add 20 more in the near future.

|

| Press operator Mike Urik worked at Oberg for six years and went through the apprenticeship program, then left the company, only to return five years later. “I started on the press floor, and they saw that I was a hard worker,” he says, “so I was placed on some special jobs and projects and have moved up.” |

For employees already in the Oberg Industries fold, the company has embarked on a project-management initiative.

“We are providing formal training for about 20 employees whom we have identified as having the skills and abilities to become project managers,” says Wagner, describing the 2-yr.-old program. Training includes classroom and on-the-job instruction, with management selecting a few projects where trainees can learn to report and analyze data, and follow work through the manufacturing process. Project managers form a bridge between management and shop-floor personnel, with all parties benefitting from the exchange of ideas and information, according to Wagner.

“Front-office personnel may not als understand what exactly occurs on the shop floor, and the employees on the floor may not understand front-office concerns,” he says. “We’ve tried to bridge that gap, and the feedback through our project-management initiative helps do that.” MF

|

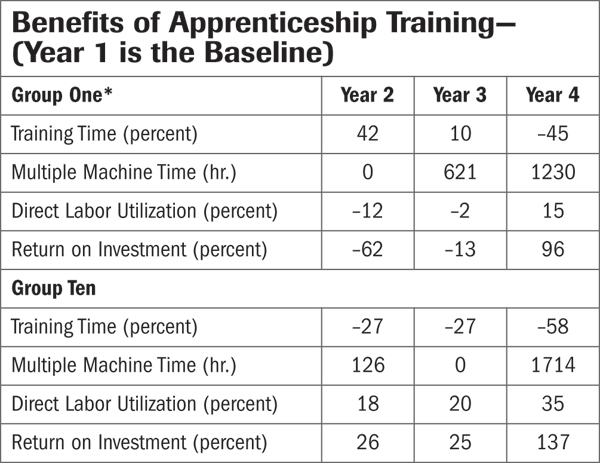

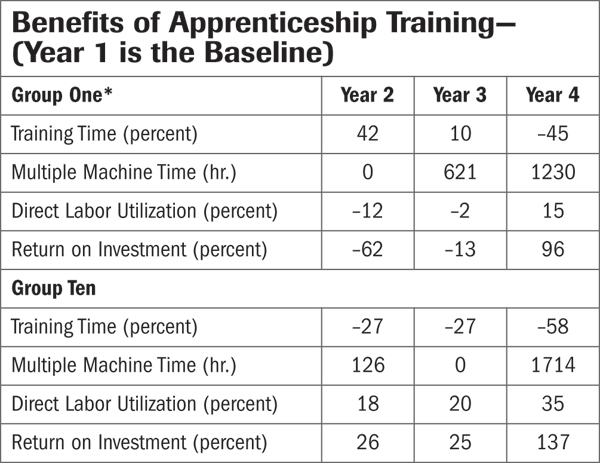

Tracking Training—ROI by the Numbers

Training can be a

feel-good term. While every company boasts of training efforts, return

on investment (ROI) can be elusive. Not so at Oberg Industries, where

all sorts of training data illustrate an efficient ROI.

The shift

from time-based to competency-based apprenticeship training has enabled

the company to know, with certainty, what each graduate can do,

according to Greg Chambers, Oberg director of corporate compliance.

|

| *This chart tracks apprentices in a variety of job classifications at Oberg Industries. Group One was the first group to go through the competency-based apprenticeship program, while Group Ten was the most recent group to complete it. Completion of an apprenticeship occurs on an individual basis, but the majority of apprenticeships are completed within 4 yr. |

“This

is critical in a work environment where you have a constantly changing

product mix,” he says, “and competency-based training provides us with

the ability to quickly move human resources to areas with the greatest

need.

”The training shift a from a rigid length of time also

benefits employees, allowing them to more quickly earn higher wages

associated with increased training, and more quickly attain skills that

make them valuable assets, thus assisting in job and career security.

Training

time is the percentage of work an employee’s time charged to training.

For example, in Group One, Year 2 training time rose by 42 percent over

Year 1. With each passing year, training time decreases, with the

percentage representing a change from the Year 1 baseline. So in Year 4,

Group One charged 45 percent less time to training than in Year 1,

while for Group Ten training time decreased by 58 percent compared to

Year 1. Ideally, the time charged to training should decrease, with more

time charged to production.

Multiple machine time tracks the

ability of one operator to run multiple machines, a huge push at Oberg,

where the company strives for cellular and lights-out manufacturing.

Group One failed to register any multiple-machine time in Year 1 or Year

2, as its members did not learn their craft well enough to run multiple

machines until Year 3. By Year 4, training had resulted in more than

1000 hours spent running multiple machines. Group Ten shows a similar

trend.

Direct labor utilization tracks the amount of time an

apprentice spends performing direct labor, as opposed to time spent

training, performing maintenance or doing other tasks not directly

related to production. For example, Group One had a 15-percent increase

in Direct Labor Utilization for Year 4 apprentices relative to their

first year. The percentage trend is even more impressive when

considering the employees’ increasingly complex job assignments each

year.

ROI represents how apprentices are bringing revenue to

Oberg. By Year 4, Group One apprentices generate $96 for each dollar

spent on training. The return is even greater for Group Ten apprentices,

reflecting improvement in worker performance as the competency-based

apprenticeship program evolves.

|

See also: Oberg Industries, LLC

Technologies: Management, Training

Lou Kren

Lou Kren A home-grown apprenticeship program serves as the lynchpin of Oberg Industries’ world-class training efforts. The metalformer, die designer and die builder is based in Freeport, PA, and registered $105 million in sales in 2011, 30 percent higher than 2009, when Oberg, along with the rest of the stamping industry, faced tough times. Since 2009, the company also has invested in people and technology, raising employment by 11 percent. In sum, Oberg adeptly juggles its differing machinery and diverse customer base via a highly trained, highly motivated workforce—precisely why the company is a Hitachi Foundation Pioneer Award winner.

A home-grown apprenticeship program serves as the lynchpin of Oberg Industries’ world-class training efforts. The metalformer, die designer and die builder is based in Freeport, PA, and registered $105 million in sales in 2011, 30 percent higher than 2009, when Oberg, along with the rest of the stamping industry, faced tough times. Since 2009, the company also has invested in people and technology, raising employment by 11 percent. In sum, Oberg adeptly juggles its differing machinery and diverse customer base via a highly trained, highly motivated workforce—precisely why the company is a Hitachi Foundation Pioneer Award winner.

Podcast

Podcast