The Studio System employs Desktop Metal’s Bound Metal Deposition (BMD) technology, where rods of metal powder and binders are heated and extruded to shape a part. This eliminates the loose powders and lasers employed in laser powder bed fusion, a process that necessitates a high initial investment. These factors swayed APG in its purchase decision, according to APG officials. The BMD technology enables a range of material printing, including H13 tool steel, 4140 steel, 316L stainless steel and 17-4 PH stainless steel.

When exploring the use of metal 3D printing, APG tested

parts printed on the Studio System for their dimensional tolerances and

metallurgical properties. Overall, APG engineers found that printed parts had

tolerances comparable to traditionally manufactured parts. To evaluate material

properties, APG engineers printed a number of sample parts, then halved them for

examination of metal density and grain structure. Tests revealed that the

printed metals showed hardness levels, density and grain structure in line with

parts created via MIM.

When exploring the use of metal 3D printing, APG tested

parts printed on the Studio System for their dimensional tolerances and

metallurgical properties. Overall, APG engineers found that printed parts had

tolerances comparable to traditionally manufactured parts. To evaluate material

properties, APG engineers printed a number of sample parts, then halved them for

examination of metal density and grain structure. Tests revealed that the

printed metals showed hardness levels, density and grain structure in line with

parts created via MIM.

“The Studio System is enabling us to constantly be asking ourselves how can we do this better, resulting in significant time and cost savings,” says Nate Higgins, APG business unit manager.

Asking that question has proven valuable, as success stories

abound at APG.

For example, rather than requiring staff to manually tighten

and loosen part fixtures, engineers designed a custom-made ratchet screwdriver

tool to automate the process. Using the Studio System, they printed the tool,

with its complex ratchet assembly, in only a few days from 17-4 PH stainless

steel. APG officials note 93-percent cost savings and 87-percent time savings as

compared to traditional manufacturing. The tool allows a single operator to run

as many as five CNC machines at a time, producing a more efficient workflow and

significant labor-cost savings.

Also produced through APG’s 3D printing capability, coining fixtures, which require custom geometry for each application and superior wear resistance to withstand repeated use cycles. Using the Studio System, APG printed an inhouse-designed coining fixture from 17-4 stainless steel and begin employing it in only three days. Overall, the new 3D-printed fixture offered 76-percent cost savings and 84-percent time savings as compared to traditional manufacturing.

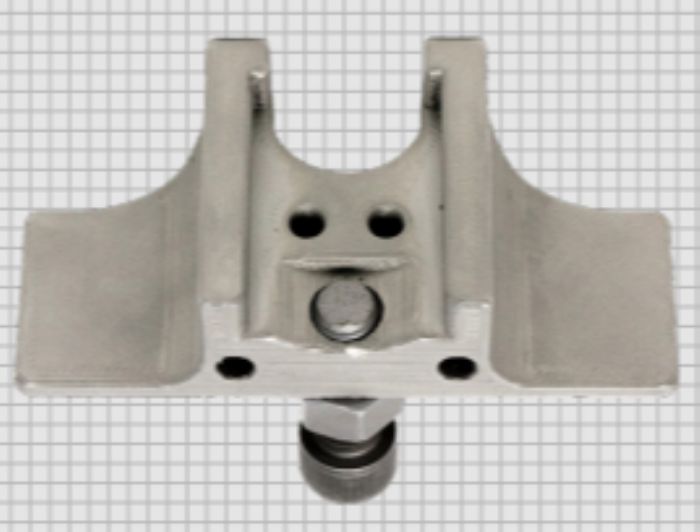

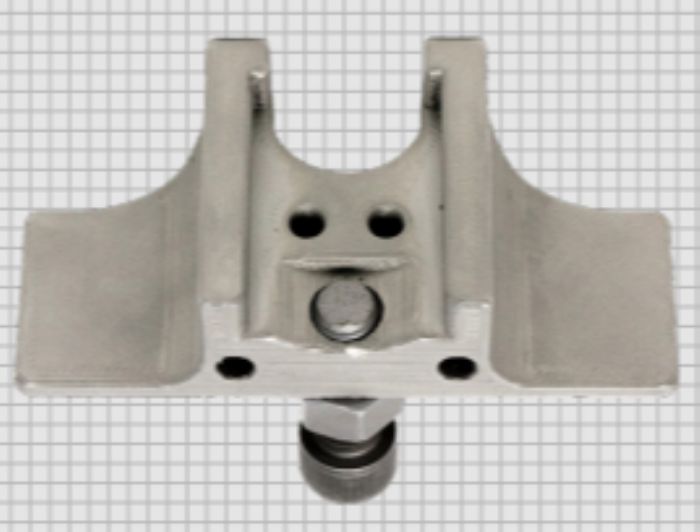

Another fixture, used to push a thread-checking tool into a

part, and again printed on the Studio System from 17-4 PH stainless steel,

resulted in time savings of 90 percent versus traditional machining. And, APG

printed the fixture for less than $100, whereas traditional machining would

result in a $600 price tag.

Another fixture, used to push a thread-checking tool into a

part, and again printed on the Studio System from 17-4 PH stainless steel,

resulted in time savings of 90 percent versus traditional machining. And, APG

printed the fixture for less than $100, whereas traditional machining would

result in a $600 price tag.

When 3D printing these and other internal-use parts, APG

found that nearly all could proceed directly to use without post-machining. For

some parts destined for customers, secondary machining was necessary to ensure

surface-finish or hole-size requirements.

However, APG engineers believe that they can avoid such steps by working

with customers early in the design process to identify critical part features.

In addition to the cost and time savings, 3D printing has

translated into an increase in manufacturing capacity. APG can turn around

customer jobs more quickly while freeing capacity in its machine shop for other

work.

See also: Desktop Metal, Inc.

Technologies: Additive Manufacturing

This enables significant lightweighting of parts, in some

cases by as much as 30 percent, resulting in less wear-and-tear on machinery

and less downtime on the manufacturing floor. In addition, the technology has

opened the door to designing improved workflows, particularly related to

machining, which, otherwise, may be too time- and labor-intensive to pursue. A

main target for those improvements: post-processing of parts in CNC machines.

This enables significant lightweighting of parts, in some

cases by as much as 30 percent, resulting in less wear-and-tear on machinery

and less downtime on the manufacturing floor. In addition, the technology has

opened the door to designing improved workflows, particularly related to

machining, which, otherwise, may be too time- and labor-intensive to pursue. A

main target for those improvements: post-processing of parts in CNC machines.

When exploring the use of metal 3D printing, APG tested

parts printed on the Studio System for their dimensional tolerances and

metallurgical properties. Overall, APG engineers found that printed parts had

tolerances comparable to traditionally manufactured parts. To evaluate material

properties, APG engineers printed a number of sample parts, then halved them for

examination of metal density and grain structure. Tests revealed that the

printed metals showed hardness levels, density and grain structure in line with

parts created via MIM.

When exploring the use of metal 3D printing, APG tested

parts printed on the Studio System for their dimensional tolerances and

metallurgical properties. Overall, APG engineers found that printed parts had

tolerances comparable to traditionally manufactured parts. To evaluate material

properties, APG engineers printed a number of sample parts, then halved them for

examination of metal density and grain structure. Tests revealed that the

printed metals showed hardness levels, density and grain structure in line with

parts created via MIM. Another fixture, used to push a thread-checking tool into a

part, and again printed on the Studio System from 17-4 PH stainless steel,

resulted in time savings of 90 percent versus traditional machining. And, APG

printed the fixture for less than $100, whereas traditional machining would

result in a $600 price tag.

Another fixture, used to push a thread-checking tool into a

part, and again printed on the Studio System from 17-4 PH stainless steel,

resulted in time savings of 90 percent versus traditional machining. And, APG

printed the fixture for less than $100, whereas traditional machining would

result in a $600 price tag.