Lou Kren

Lou KrenAutomation, Industry 4.0 Driving Advanced Material Handling Solutions

April 26, 2023Comments

Very simply put, material handling is defined as moving materials. Just how that occurs greatly impacts a manufacturer’s bottom line. Given these facts, approaches and technologies have evolved to deliver increased efficiency and better balance sheets, according to various material handling product and service providers. Automation and Industry 4.0 are driving advances, and here’s a look at just how in these unique leading-edge examples that are making headway on shop floors, as well as some sound advice on extending the life of material handling equipment. Find more on material handling technology, including conveyor options and methods to keep material and parts safe and blemish-free during transport.

Optimize Part and Material Routing—Software Helps

On the shop floor, the most effective material handling strategy emphasizes travel distance and timing, note officials from Stratawise, LLC, Tampa, FL, a provider of workflow software and other supply-chain products and services. Minimize production costs by “moving the right material to the right place, at the right time, in the right amount, in sequence, and in the right position or condition,” reads the Stratawise mantra.

On the shop floor, the most effective material handling strategy emphasizes travel distance and timing, note officials from Stratawise, LLC, Tampa, FL, a provider of workflow software and other supply-chain products and services. Minimize production costs by “moving the right material to the right place, at the right time, in the right amount, in sequence, and in the right position or condition,” reads the Stratawise mantra.

Crucial to doing so is a proper production-system setup—much easier in a greenfield scenario where a plant can be built with specific production in mind. In currently operating environments, challenges abound in optimizing material flow and improving material handling/production ratios, but overall, remember the number-one objective of material handling: Reduce unit costs of production.

Toward this objective, Stratawise offers these subgoals:

- Maintain or improve product quality, reduce damage and provide for protection of materials.

- Promote safety and improve working conditions.

- Promote productivity.

The third subgoal appears vague, so the company offers additional guidance on promoting productivity. Material should flow in a straight line, and should move as short a distance as possible. Also, try to move as much material as possible at one time. Mechanizing and/or automating material handling helps with all of the above and aids greatly in improving throughput.

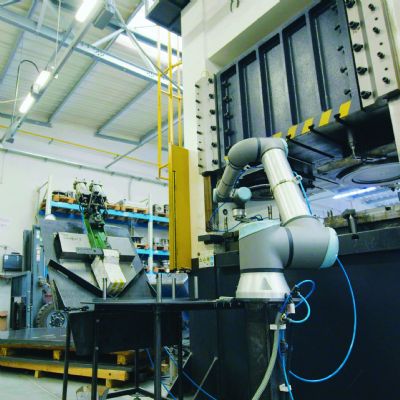

For more efficient movement of parts and part material on the shop floor, advises Stratawise, purchase versatile equipment, and standardize carts, racks and conveyors where possible to ease interchangeability and maintenance. On the front end, automating material feed equipment for production equipment such as stamping presses obviously can improve productivity while freeing manual labor for other tasks.

Of course, hiccups occur, perhaps in part material delivery and supply, in production or material handling equipment that breaks down for whatever reasons, etc. All of this favors the manufacturer that plans for the unplanned. Fortunately, sensing, monitoring and analysis technology exists to streamline part and part-material handling, warn of possible bottlenecks, and provide possible solutions. Software ties all of this together. For example, Stratawise offers its StrataFlows automated visibility, communication and control software for various needs all along the supply chain, including real-time analysis of material handling operations in a manufacturing environment, as well as material inflow and outflow.

Of course, hiccups occur, perhaps in part material delivery and supply, in production or material handling equipment that breaks down for whatever reasons, etc. All of this favors the manufacturer that plans for the unplanned. Fortunately, sensing, monitoring and analysis technology exists to streamline part and part-material handling, warn of possible bottlenecks, and provide possible solutions. Software ties all of this together. For example, Stratawise offers its StrataFlows automated visibility, communication and control software for various needs all along the supply chain, including real-time analysis of material handling operations in a manufacturing environment, as well as material inflow and outflow.  The AGVs described above are part of a larger family of robotic vehicles designed to propel parts, products and material throughout the shop floor. Within this family reside autonomous mobile robots (AMRs) with a twist. The twist: robotic base units that dock with motorized carriers, according to FlexQube, a Swedish material handling-products company with its U.S. base in Duncan, SC. This “one robot/multi-carrier” concept, as the company dubs it, consists of a non-load-carrying AMR housing safety, navigation and battery, which can dock with motorized carriers via a standard coupling device. The coupling device transfers power and data to the motors to enable navigation throughout a plant. Modular and flexible carriers are configured to specific part and material loads, and can reside where needed until transport via the AMR.

The AGVs described above are part of a larger family of robotic vehicles designed to propel parts, products and material throughout the shop floor. Within this family reside autonomous mobile robots (AMRs) with a twist. The twist: robotic base units that dock with motorized carriers, according to FlexQube, a Swedish material handling-products company with its U.S. base in Duncan, SC. This “one robot/multi-carrier” concept, as the company dubs it, consists of a non-load-carrying AMR housing safety, navigation and battery, which can dock with motorized carriers via a standard coupling device. The coupling device transfers power and data to the motors to enable navigation throughout a plant. Modular and flexible carriers are configured to specific part and material loads, and can reside where needed until transport via the AMR.

Webinar

Webinar