Use the Tools

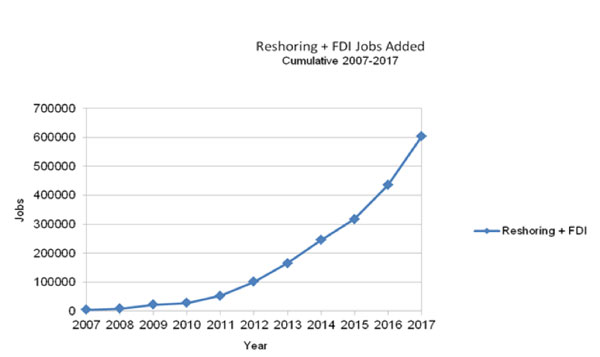

Tools offered by the Reshoring Initiative are well worth getting to know. For example, the organization’s Library shows industries and companies that are reshoring, and could be a potential source of new business for metalformers.

National Metalworking Reshoring Award Eligibility 1) Reshoring of work that occurred between January 1, 2013 and December 31, 2018. 2) Work came back from outside North America to North America. 3) Products, parts or tooling reshored must be made primarily by forming, casting, fabricating or machining, including additive manufacturing. 4) Application must be submitted by January 31, 2019.

The award winner will be announced on March 8, 2019, at the MFG Meeting in Tucson, AZ. For details, visit www.reshoringnow.org.

|

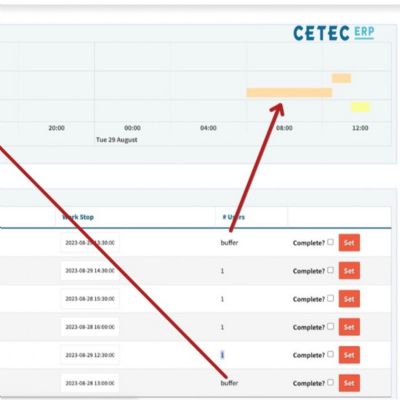

Another tool, the TCO Estimator, can help metalformers and their customers make better sourcing decisions. It helps companies account for all relevant factors—overhead, balance sheet, risks, corporate strategy and other external and internal business considerations—to determine the true total cost. Many companies find that rising offshore labor rates, combined with other hidden costs of offshoring, often counterbalance any remaining savings from cheap prices or labor abroad.

A real-world example of a company that used the Estimator to sell against imports is EMS contract manufacturer, Morey Corp., Woodridge, IL.

Morey, while competing against a lower-priced Asian company for a $60-million electronics build opportunity, used the TCO Estimator to show a customer that although Morey’s price was higher, its TCO was lower. “We used the TCO calculator to the costs and risks of both options and was a crucial piece to our winning strategy,” says Tony Woodall, Morey’s vice president of sales.

Another Reshoring Initiative program, the Import Substitution Program (ISP), creates opportunities for U.S. companies to compete against imported products, leading to reshoring. Designed to enable companies, industry associations, equipment suppliers and economic developers to substitute domestic production for imports, ISP identifies and qualifies relevant importers as reshoring candidates. Companies can keep current with ISP updates by signing up for the Reshoring Initiative eNewsletter.

Finally, we welcome news of reshoring and foreign-direct-investment successes. Share yours at info@reshorenow.org and we’ll provide you with publicity and a “Manufacturing Is Cool” t-shirt. And don’t forget to enter the National Metalworking Reshoring Award Competition. See box for details. MF

See also: Reshoring Initiative

Technologies: Bending, Management

Harry Moser

Harry Moser