Brad Kuvin

Brad KuvinWire DED for Printing Large Metal Parts

August 22, 2019Comments

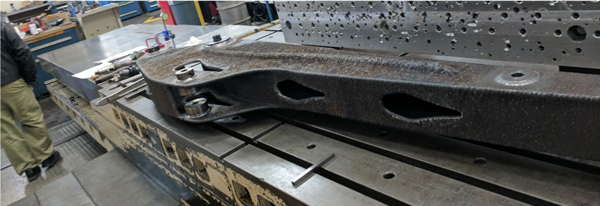

In May of this year, Lincoln Electric penned an updated agreement with Oak Ridge National Laboratory (ORNL) to expand its large-scale additive manufacturing (AM) development work to manufacture metal components using its automated wire directed energy deposition (DED) technology at deposition rates exceeding 100 lb./hr. The work, ongoing at the ORNL Demonstration Facility and supported by the U.S. Department of Energy, aims in part to support efforts by U.S. manufacturers to apply AM technology in the development of large tools, dies and molds. The announcement came on the heels of the acquisition by Lincoln Electric of Baker Industries, Inc., Detroit, MI, a manufacturer of custom tooling, fixtures and other components, primarily for the automotive and aerospace industries. The result: the ability of Lincoln Electric to nurture and scale its new metal AM service business in Cleveland, OH.

In May of this year, Lincoln Electric penned an updated agreement with Oak Ridge National Laboratory (ORNL) to expand its large-scale additive manufacturing (AM) development work to manufacture metal components using its automated wire directed energy deposition (DED) technology at deposition rates exceeding 100 lb./hr. The work, ongoing at the ORNL Demonstration Facility and supported by the U.S. Department of Energy, aims in part to support efforts by U.S. manufacturers to apply AM technology in the development of large tools, dies and molds. The announcement came on the heels of the acquisition by Lincoln Electric of Baker Industries, Inc., Detroit, MI, a manufacturer of custom tooling, fixtures and other components, primarily for the automotive and aerospace industries. The result: the ability of Lincoln Electric to nurture and scale its new metal AM service business in Cleveland, OH.

“We are uniquely aligned to collaborate with ORNL and continue to expand the capabilities of wire DED,” explains Tom Matthews, senior vice president for technology and R&D at Lincoln Electric, during our recent visit with key members of the company’s AM team.

“We understand deposition technology and how to deposit molten metal,” adds Mark Douglass, business development manager, additive solutions. “And, our team of inhouse engineers and metallurgists will lead the development of new wire feedstocks needed to expand the capabilities of the process. We’ll be focusing on, among other variables, the thermal cycling that occurs during deposition, and the development of detailed and precise robot-motion profiles—coordinated with other automation devices—to ensure precision, even as speed and deposition rate rise.”

Developing and fine-tuning the robot path, and learning to take advantage of the free motion available during robotic DED, enables molten-metal deposition at the right orientation to leverage gravity and avoid the need for supports. That’s just one of the advancements resulting from the development of enhanced and proprietary software from Lincoln Electric.