Unique Thread-Form Taps for High-Volume CNC Production

May 1, 2014Comments

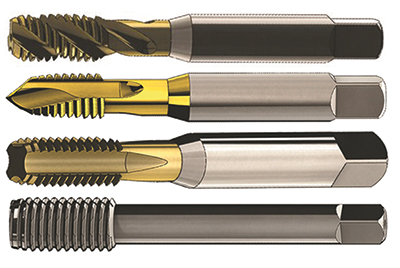

Machinists now can add a locking feature to tapped holes by using specialized and newly refined Spiralock taps from Stanley Engineered Fastening, Shelton, CT, optimized for extended tool life in high-volume CNC operations. The taps are based on a unique thread form that resolves the thread-loosening and joint-integrity problems common to standard fasteners.

Machinists now can add a locking feature to tapped holes by using specialized and newly refined Spiralock taps from Stanley Engineered Fastening, Shelton, CT, optimized for extended tool life in high-volume CNC operations. The taps are based on a unique thread form that resolves the thread-loosening and joint-integrity problems common to standard fasteners.

In traditional 60-deg. threads, the gap between the upper edges of the male and female threads can lead to vibration-caused loosening. Stress concentration and fatigue at the first few engaged threads also can be a problem. The unique profile of Spiralock threads closes the gap that causes loosening, improving the integrity and reliability of threaded joints.

Thread-form tapping has traditionally been a relatively slow machining operation, due to its limited visibility and necessary precision. Not content to let tapping technology become stale, Stanley Engineered Fastening has improved its lineup of machine taps by enhancing the tool’s geometry, surface coatings and flute angles, as well as shapes and nose size. These improvements promise to enable higher-speed production and significantly extend tool life. PVD coatings enable tapping as much as 50-percent faster than with previous nitride or bright finished taps, and help the taps to cut smoothly in deeper holes where there is little coolant or lubrication. Also available: a dual-layer PVD coating.

Spiralock: 800/521-2688; www.spiralock.com

See also: Stanley Engineered Fastening

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Tooling

ToolingPrecision Tool Building via Precision Wire EDM

Lou Kren Friday, August 25, 2023

Tooling

ToolingNew Die Steel Reduces Wear on Form Details

Brad Kuvin Monday, February 27, 2023