Peter Ulintz

Peter UlintzStretching and Drawing

June 1, 2009Comments

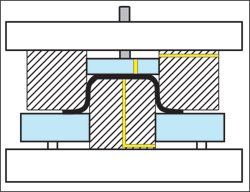

Troubleshooting forming problems in the press shop requires a good understanding of forming modes and process variables. Perhaps the most challenging forming modes to isolate are stretching and drawing. Because the process variables that influence each mode can differ significantly, an accurate assessment is essential before making changes to the tooling or stamping process. Changing a tooling parameter that promotes material stretching will not solve a drawing-related problem; good examples are punch and die radii. In stretching operations, the critical radius is the punch radius. The punch radius must be very smooth and large enough to promote material stretching across the face. The die radius is relatively small in stretching operations to restrict material flow over the die surface. In addition, the pressure pad is usually rough to inhibit material flow, thus forcing the material in contact with the punch to stretch.

On the other hand, the opposite parameters are required for drawing modes. Here, stretching material across the punch face is not desirable; therefore, the punch radius will be relatively small and the punch face left rough. The rough surface creates high friction between the punch and the sheetmetal, inhibiting material stretching, which in turn forces material to draw over the die surface toward the cavity. The die face and die radius are highly polished and the die-entry radius is made as large as possible—short of causing wrinkles—to ease material flow into the die cavity.

A brief comment regarding die craftsmanship and quality: In general, tool and die makers take great pride in their work. It is not uncommon to find every die component highly polished and meticulously prepared prior to final assembly. The polished components communicate a perception of quality to anyone that sees the die. Unfortunately, this quality perception can cause many problems. Regardless of the impression that a tool may leave, its primary purpose is function, not aesthetics. Smoothing and polishing the face of the draw punch, for example, significantly reduces friction in an area where friction is desired to help draw in the flange. One must be careful not to sacrifice function for aesthetics.

The location of die-process lubricant on the sheetmetal blank is critical in drawing and stretching operations. Stretching operations require lubrication between the sheetmetal and the punch face to provide a low-friction site for the material to slide and stretch. Meanwhile, the sheetmetal on the die surface should not be lubricated, creating high friction to inhibit material draw-in.

In deep-drawing processes, the sheetmetal surface under the punch should not be lubricated so there is higher friction between the punch face and workpiece. The die surface and die-entry radius should be lubricated to ease material flow. These very important lubrication conditions often are overlooked in the press shop. Often times, lubrication is applied to the entire sheet before it enters the die without any consideration for the forming modes. Small changes in lubrication quantity in critical zones on a stamping can mean the difference between drawing and stretching. Improper lubrication complicates problem solving and contributes to inconsistent part quality.