Stamper Adds Tailout Feeder to Boost Material Utilization

December 1, 2012Comments

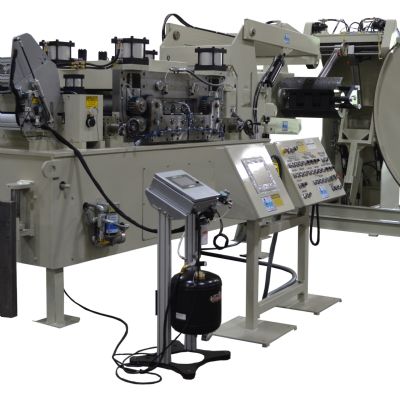

Tier Two automotive stamper Kalida Manufacturing Inc., Kalida, OH, a division of KTH Industries, has added a Coe Press tailout (or secondary) feeder to one of its press lines, and as a result is experiencing a reduced scrap rate, and a safer process as well. The feeder, installed to deliver material to a Minster E4H-800 four-point press, resides downstream of a servo-feed unit, and telescopes through the press columns and into the die area. This arrangement reduces scrap, and also results in less material being left in the die—that makes moving remaining material quicker and safer. Coe custom-designed the tailout feeder—4-in.-dia. upper rolls and 5-in.-dia. lower driven roll—to attach directly to the existing servo-feed unit.

See also: Coe Press Equipment Corporation

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingFour Before the Floor—Dallas Industries at FABTECH 2023

August 21, 2023

Video

Video