Press Brakes Double Production of Humvee Up-Armor Kits

November 1, 2008Comments

Around-the-clock production is a life

and death matter for BAE Systems’s armored-vehicle complex in West Chester, OH, says Dan Sizemore, plant manager of the facility that fabricates up-armor kits for military Humvee vehicles. The plant operates 24/7 churning out underbody armor components to increase Humvee protection against land mines and other explosive devices. Conflicts in Iraq and Afghanistan have demanded tremendous boosts in production volumes, according to BAE plant manager Dan Sizemore: Output of truck-armor sets has doubled, from 40 to 80 sets per day, over the past two years.

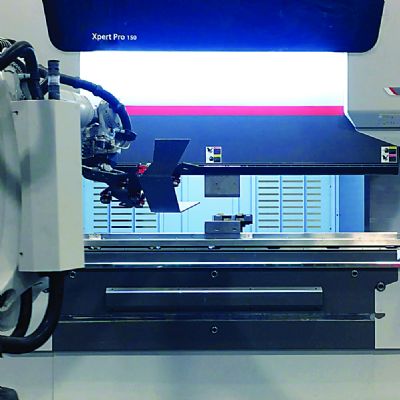

BAE Systems’s armored-vehicle complex As part of its expanding armor-fabrication operations, the plant relies on accurate press-brake bending to deliver bend precision and consistency, essential for downstream robotic welding. “We have to present accurate parts to the robot,” Sizemore stresses. “The robot goes to the same spot every time. If a bend is off, the set is ruined. For this kind of automated production, variation is the devil.”

To minimize bend variation, the BAE plant standardized on one model of press brake, Proform machines from Cincinnati Inc., Cincinnati, OH, along with interchangeable dies and programs. “We’re able to standardize our training, our tooling, bends, programs and methods, and our maintenance,” says Sizemore. “Along with reducing variation, this gives us maximum flexibility in scheduling and assigning personnel.”

Precision servo hydraulics on a highly rigid, heavyweight platform allow the Proform brakes to hold ram repeatability to ±0.001 in. Each of four fabricating cells in the plant boasts a pair of press brakes. Between the cells, BAE installed six 90-ton Proform press brakes and two 350-ton brakes to handle its mix of part sizes. Each cell bends seven underbody armor parts—four on one press brake, three on the other.

“Standardized press sets and dedicated setups for each cell allow us to drive downtime and maximize throughput,” Sizemore says.

Cincinnati Incorporated: 513/367-7100; www.e-ci.com

See also: Cincinnati Inc.

Technologies: Bending