A post to the MultiCam Canada website summarizes the benefits of waterjet cutting:

• Versatility—Waterjet cutting can be used to machine reflective materials such as copper and aluminum as well as heat-sensitive materials. The machines also require little to no setup changes when switching from cutting thin to thick materials.

• No heat-affected zone (HAZ)—Waterjet cutting does not heat the material nor change its properties, so there is no HAZ and no thermal distortion occurs.

• Environmentally friendly—Abrasive waterjet systems use garnet, which is a non-reactive biologically inert mineral.

• Safe—Waterjets do not heat or melt the workpiece material, so they produce no noxious fumes nor pose a risk of fire.

• Tight tolerances—On thinner parts, waterjet-cutting machines and lasers offer comparable tolerances, but on parts thicker than 0.5 in., waterjet cutting typically yields tighter tolerances.

• Can machine thicker materials—Shops can waterjet-cut materials to 3 in. thick (or more), while most lasers have a maximum practical cutting thickness of 0.75 in.

• Good edge finish—Waterjet-cut parts typically exhibit fine, sand-blasted surfaces because of the the material is abraded.

Let’s go shopping for some new waterjet-cutting technology.

Waterjet-Cut the Most Challenging of Materials Sugino Corp., Itasca, IL, introduces the Katana2 ultrahigh-pressure waterjet-cutting machine, ideally suited for cutting titanium, stainless steel, carbon-fiber reinforced polymers (CFRPs) and other hard materials such as copper and glass. Utilizing Sugino’s newly developed extra-fine abrasive nozzle (0.3- to 1.5-mm dia.), the Katana2 can achieve cutting diameters as low as 0.012 in. at pressures as high as 43,500 PSI.

Sugino Corp., Itasca, IL, introduces the Katana2 ultrahigh-pressure waterjet-cutting machine, ideally suited for cutting titanium, stainless steel, carbon-fiber reinforced polymers (CFRPs) and other hard materials such as copper and glass. Utilizing Sugino’s newly developed extra-fine abrasive nozzle (0.3- to 1.5-mm dia.), the Katana2 can achieve cutting diameters as low as 0.012 in. at pressures as high as 43,500 PSI.

With a footprint of only 57 by 81 in., the Katana2 also is eco-friendly, promising to minimize the consumption of abrasive materials and power. Cutting area: 9.5-in. x axis, and 8-in. y and z axes.

Sugino Corp.: 888/784-4661; www.suginocorp.com

CNC Cutting Machine Combines Waterjet and Plasma Capabilities

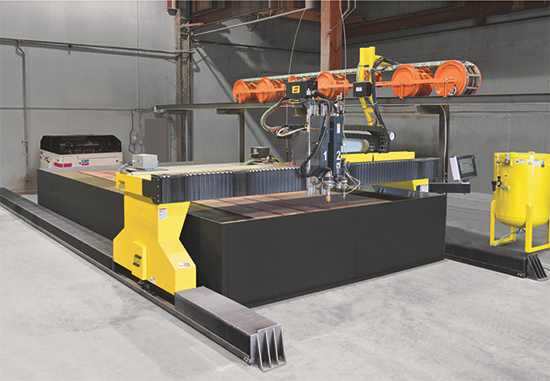

Esab Cutting Systems, Florence, SC, introduces the Hydrocut LX shapecutting machine, combining waterjet and plasma systems operating on the same gantry. Fabricators can cut precision contours with the waterjet, and noncritical contours with plasma. The machine boasts a heavy-duty gantry with a high-stiffness beam design featuring dual precision linear rails and rack-and-pinion drives. Equip it with as many as four waterjet stations and two high-definition plasma stations (Esab’s m3 Precision Plasmarc). Powering its waterjet action is a KMT 90,000-PSI pump.

Esab Cutting Systems, Florence, SC, introduces the Hydrocut LX shapecutting machine, combining waterjet and plasma systems operating on the same gantry. Fabricators can cut precision contours with the waterjet, and noncritical contours with plasma. The machine boasts a heavy-duty gantry with a high-stiffness beam design featuring dual precision linear rails and rack-and-pinion drives. Equip it with as many as four waterjet stations and two high-definition plasma stations (Esab’s m3 Precision Plasmarc). Powering its waterjet action is a KMT 90,000-PSI pump.

At the helm: Esab’s Vision T5 control and Columbus III CAD/CAM programming and nesting software, designed specifically for plasma, oxyfuel, laser and waterjet cutting. The software handles simple to highly complex cuts, multiprocess cuts, labeling and nesting jobs.

Esab Welding & Cutting Products: 888/372-2288; www.esab-cutting.com

CAM Software Develops 2D Profiles, 3D Pathing

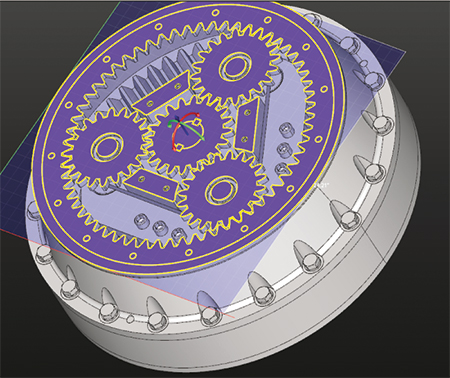

Using new Intelli-Cam advanced computer-aided manufacturing software from Omax Corp., Kent, WA, engineers can generate 2D and 3D waterjet-cutting tool paths from 3D models. Import a 3D file in one of the many supported file types and the 3D object appears in an interactive window; generating a 2D profile from any face or slice is just a click a. 3D pathing is just as easy, with the AutoPath function creating the tool path and applying the required attributes for 3D cutting before exporting.

Free to Omax machine owners, Intelli-Cam is part of the firm’s Intelli-Max software suite. “Job shops will benefit from Intelli-Cam since they will rarely ever again have to ask their customers to resave a file to a format they can accept, because now they can accept nearly all of them,” says Omax software architect Carl Olsen.”

Free to Omax machine owners, Intelli-Cam is part of the firm’s Intelli-Max software suite. “Job shops will benefit from Intelli-Cam since they will rarely ever again have to ask their customers to resave a file to a format they can accept, because now they can accept nearly all of them,” says Omax software architect Carl Olsen.”

Among the software’s standard features:

• Can run as a standalone application, or integrated into many popular 3D CAD systems;

• Supports a wide range of neutral and native 3D file formats, including CATIA, SolidWorks, ACIS, Inventor, Step, Siemens NX and more; and

• Offers single-click export to an Omax CAD file or open direct into Omax Intelli-Max Layout or Make.

Omax Corp.: 253/872-2300; www.omax.com

Controls and Software at the Heart of Every Sleek Cutting System

Bystronic, Elgin, IL, introduced FABTECH visitors to its ByVision Control programming interface, boasting a full 15-in. touchscreen that allows users of waterjet- and laser-cutting machines to quickly maneuver through screen selections for efficient setup and operation. The ByVision user interface operates within a Windows XP professional platform for speed and network compatibility.

Bystronic, Elgin, IL, introduced FABTECH visitors to its ByVision Control programming interface, boasting a full 15-in. touchscreen that allows users of waterjet- and laser-cutting machines to quickly maneuver through screen selections for efficient setup and operation. The ByVision user interface operates within a Windows XP professional platform for speed and network compatibility.

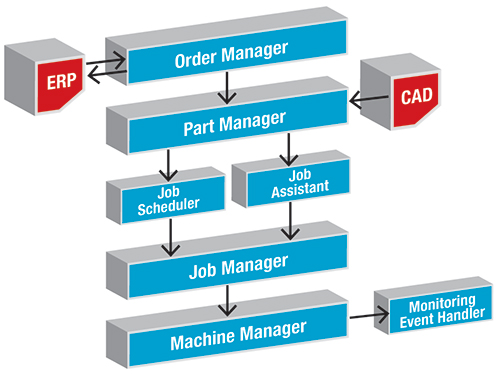

The firm’s popular Bysoft CAD/CAM software has a new addition: the Plant Manager Cutting (PMC) module. It finds use for fact-based planning and monitoring of all waterjet- and laser-cutting processes. The PMC automatically processes order and CAD data independent of any programmer intervention, eliminating the time required for cutting-plan preparation and feedback to the production-planning system. Managers gain access to critical decision-making data including load balancing of each machine, order volume and status, and expected completion and due dates.

Bystronic Inc.: 847/214-0300; www.bystronicusa.com

High Speed, and Precise Positioning

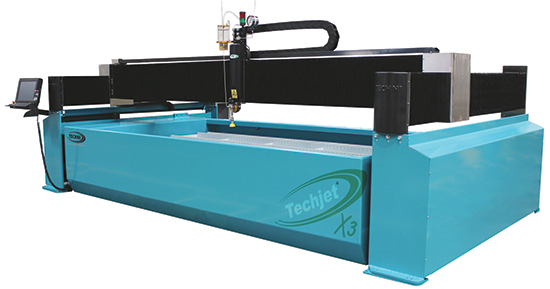

Techni Waterjet, Lenexa, KS, recently debuted its Quantum NXT electric servo pump and its TJ4100-G-X3 gantry-style waterjet-cutting machine (below). The Quantum, explained company officials at FABTECH 2013 in Chicago, employs a servo motor directly enveloping a high-load precision ball screw that houses the ceramic plungers. Pumping action results from the reciprocating plungers.

Techni Waterjet, Lenexa, KS, recently debuted its Quantum NXT electric servo pump and its TJ4100-G-X3 gantry-style waterjet-cutting machine (below). The Quantum, explained company officials at FABTECH 2013 in Chicago, employs a servo motor directly enveloping a high-load precision ball screw that houses the ceramic plungers. Pumping action results from the reciprocating plungers.

The TJ4100-G incorporates linear-scale feedback. By mapping the entire cutting area with a laser-calibrated digital encoder, the motion system is rated to a positional accuracy of 0.0005 in.; cutting speed tops out at 1000 in./min.

Also on display at FABTECH: a rotary axis that employs a direct-drive motor assembly capable of accurately (±0.1 deg.) positioning and contouring a workpiece under the cutting stream.

Techni Waterjet: 888/832-4643; www.techniwaterjet.com

Don’t Let the Small Footprint Fool You

WardJet, Tallmadge, OH, introduces the Emerald 0606 (below) (2 by 2 ft.) and the Emerald 0612 (2 by 4 ft.) waterjet-cutting machines to its existing Emerald series. The smallest waterjet ever manufactured by WardJet, the Emerald 0606 reportedly offers the quality of a large, expensive waterjet-cutting system at a reduced size and cost. Because of its rigid, sturdy tank design, the Emerald 0606 can cut 12-in. stainless steel just as easily as a 2-in. sheet of foam.

WardJet, Tallmadge, OH, introduces the Emerald 0606 (below) (2 by 2 ft.) and the Emerald 0612 (2 by 4 ft.) waterjet-cutting machines to its existing Emerald series. The smallest waterjet ever manufactured by WardJet, the Emerald 0606 reportedly offers the quality of a large, expensive waterjet-cutting system at a reduced size and cost. Because of its rigid, sturdy tank design, the Emerald 0606 can cut 12-in. stainless steel just as easily as a 2-in. sheet of foam.

The Emerald 0606 offers 12 in. of Z-axis travel, and features ballscrew drives and a cantilever-style arm. This short-travel, cantilever architecture effectively balances the reduced machine footprint, say company officials, and minimizes the number of moving parts while maximizing cutting envelope and maintaining overall stiffness.

The Emerald 0612 offers double the cutting envelope of the Emerald 0606. The cantilever-style arm is ballscrew-driven and the tank is beefed up for extra support. It can index sheets of unlimited length from front to back, while standard 4- by 8-ft. sheets of material up to 2 in. thick can be cut with greater convenience.

WardJet: 330/677-9100; www.wardjet.com

Taper Compensation All the Rage

At FABTECH, Flow International, Kent, WA, showcased its Dynamic Waterjet taper-compensation feature that it most recently made available (in May 2013) on its Mach 2c, which it calls an “affordable waterjet system.” Dynamic Waterjet previously was only available on Flow’s advanced Mach 3 and Mach 4 waterjet systems.

Dynamic Waterjet produces faster, more accurate parts by adjusting taper angle in concert with cutting speed. The feature avoids the stream lag and taper inherent with all waterjet-cutting machines, previously only minimized by reducing cutting speed. Dynamic Waterjet (with Flow’s Active Tolerance Control) counters taper and stream lag using Flow’s SmartStream mathematical models. More than just a tilting cutting head, SmartStream technology changes the angle dynamically based on cutting speed. The precision motion system can attain travel speeds to 800 in./min.

Flow Intl.: 253/850-3500; www.flowwaterjet.com

Hypertherm Promotes Newly Acquired Pump Lineup

Early in 2013, Hypertherm (Hanover, NH) announced its acquisition of waterjet-equipment manufacturer Accu-Stream. FABTECH 2013 marked Hypertherm’s display of the AccuStream of HyPrecision line of waterjet-cutting pumps, rated from 15 to 150 hp. Advanced intensifier technology, company officials explained to showgoers, promises to extend maintenance intervals, reduce maintenance time and optimize performance. Additionally, high pump reliability (large-diameter ceramic plunger to prolong seal life, among other features) reportedly drives down the total cost of ownership by as much as 20 percent when compared to competitive systems.

Early in 2013, Hypertherm (Hanover, NH) announced its acquisition of waterjet-equipment manufacturer Accu-Stream. FABTECH 2013 marked Hypertherm’s display of the AccuStream of HyPrecision line of waterjet-cutting pumps, rated from 15 to 150 hp. Advanced intensifier technology, company officials explained to showgoers, promises to extend maintenance intervals, reduce maintenance time and optimize performance. Additionally, high pump reliability (large-diameter ceramic plunger to prolong seal life, among other features) reportedly drives down the total cost of ownership by as much as 20 percent when compared to competitive systems.

Eight machine models fill out the line, including the most powerful model, HyPrecision 150D. Features include soft start capability, color-touchscreen user interface, remote operation and monitoring through Modbus TCP, and proportional pressure control.

Hypertherm: 603/643-3441; www.hypertherm.com

Five-Axis Waterjet-Cutting System Cuts Taper-Free, and Bevels

Waterjet-system manufacturer Jet Edge, Inc., St. Michael, MN, introduces the Edge X-5 five-axis waterjet system that cuts complex, taper-free and 3D parts from virtually any material. Featuring the firm’s Permalign Edge technology, the machine can cut chamfers, weld bevels and sophisticated 3D parts such as impeller blades.

Waterjet-system manufacturer Jet Edge, Inc., St. Michael, MN, introduces the Edge X-5 five-axis waterjet system that cuts complex, taper-free and 3D parts from virtually any material. Featuring the firm’s Permalign Edge technology, the machine can cut chamfers, weld bevels and sophisticated 3D parts such as impeller blades.

The Edge X-5 features an industrial PC controller designed specifically for five-axis waterjet cutting. The AquaVision Di Controller’s open-architecture design gives operators the freedom to fine-tune programs from any CAD/CAM/nesting software, using standard G&M CNC code. Its Intelligent Work Envelope automatically adjusts depending on the angle of the cut to protect the operator, material and system components.

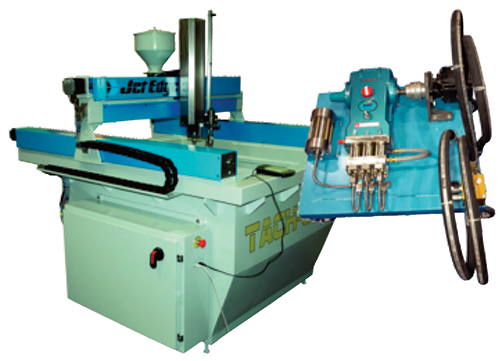

The Edge X-5, ballscrew-driven for optimal precision, features direct-couple AC brushless digital servo motors, single or double carriages, and cutting-table size from 5 by 5 to 24 by 13 ft. Also noteworthy from Jet Edge was the introduction, at FABTECH 2013, of its low-cost 40- by 40-in. table, available in three configurations, all with direct-drive pumps. Included is the Tach-Jet model (shown); its pump uses a tractor or skid-steer’s hydraulic circuit.

Jet Edge, Inc.: 763/497-8700; www.jetedge.com

View Glossary of Metalforming Terms

See also: Hypertherm, Inc., Flow International Corp., ESAB Welding & Cutting, Jet Edge Waterjet Systems, Omax Corporation

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingNew Line of Wear-Resistant Waterjet Nozzles

Friday, February 24, 2023