Laser Cutter Boasts High Throughput

May 1, 2008Comments

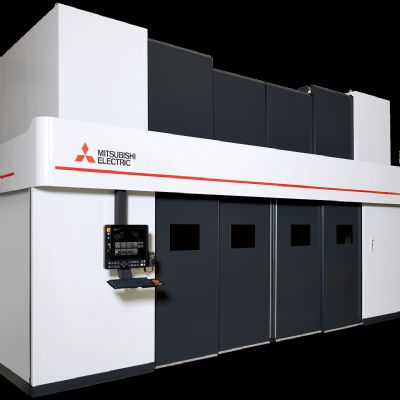

Mitsubishi Laser, through MC Machinery Systems, Inc., Wood Dale, IL, introduces the next generation of its LVPlus laser-cutting machine. The new LVPlus combines several new performance-enhancing features and its flexible automation is versatile and expandable, with several options to maximize throughput based on consumer needs.

The machine’s new 40CF-R resonator technology reduces the rise time and fall time of the square-wave pulse. This provides more consistent beam power during the cutting process and delivers a more brilliant and consistent edge quality, according to company officials. Additionally, the uniform low-current discharge provides low-power stability for improved micromachining and etching.