Joint Project Tackles Vehicle Structures via Advanced High-Strength Steel

October 1, 2007Comments

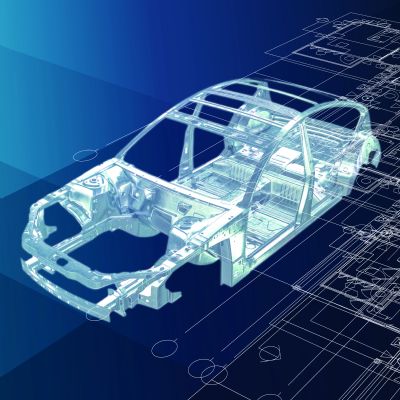

Chrysler, Daimler and the American Iron and Steel Institute (AISI) have jointly announced the success of a new project aimed at improving vehicle safety and fuel economy while reducing overall vehicle weight. By taking a holistic approach to sheetmetal structures (body-in-white) and applying new engineering computer modeling technology (topology) to generate efficient energy and load management, the latest advanced high-strength steels are utilized to achieve lighter weight objectives and improved occupant protection, according to AISI officials.

At the center of the development is topology optimization, a new computer-aided engineering (CAE) modeling tool. This program determines the areas of highest strain in the body-in-white. Once the high-strain areas are identified, the software determines the optimal location of the critical load paths to meet predetermined requirements for safety, stiffness and durability. These optimized load paths then are analyzed with respect to new advanced high-strength steels. The result reportedly is a superior structure that meets or exceeds future safety and performance standards. Also, overall vehicle weight is reduced by as much as 13 percent as compared to vehicles using conventional high-strength steels and design methods.

“Chrysler is continually developing improvements in safety and fuel economy, which are usually competing objectives,” says Bill Grabowski, director of body core engineering for Chrysler. “By working with AISI and our colleagues at Mercedes Group Research and Mercedes Benz Technologies, we are able to achieve both objectives simultaneously to achieve the most efficient solution.”

Through a cooperative effort to bring advanced steel and manufacturing technologies to future vehicles, AISI, Chrysler and Daimler have developed steel-intensive solutions to their design challenges. Chrysler products are using increasing amounts of this new technology as demonstrated in select 2008 products, including the new Chrysler Sebring.