Effective Straightening of High-Strength Materials

November 1, 2013Comments

Steel’s impact on the weight, performance and integrity of vehicles is significant, and has led to the increased use of lighter steels such as advanced high strength steels (AHSS), with tensile strengths of 1000 MPa and higher. Research shows that AHSS is the fastest-growing material in automotive applications. However, AHSS challenges stampers with greater springback, higher yield strengths, thinner materials and tougher formability. Over the past decade, stampers have gained a knowledge base helping them to deal with these challenges and have applied this to the actual die and stamping process. However, to successfully process AHSS, stampers must look at every aspect of the production line–including press-feeding operations and, in particular, straightening.

The straightening operation in a typical coil-feed line prepares the material shape so that an acceptable finished part can be produced from the flattened steel. Requirements for straightening vary depending on the material defects present and the requirements of the die and the finished part. In the case of forming operations, it may only be necessary to flatten the material sufficiently to pass easily through the die. When producing and stacking blanks for further processing, or when stamping flatness-critical parts, flatness in the continuous coil is extremely crucial.

|

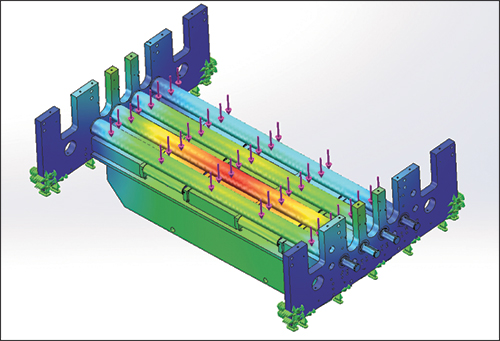

| Lower straightener rolls and backup assembly, showing stress and roll deflection from forces required to straighten AHSS. |

Straightening is most commonly accomplished by bending the strip around sets of rollers to alternately stretch and compress the upper and lower surfaces, to exceed the material’s yield and erase coil set. Then it is reformed in a so that both surfaces end up the same length after springback, resulting in flat material. When straightening AHSS, greater forces are required. This influences straightener design, including choice of components, materials and power sources.

Work Rollers for AHSS

Diameter: Straightener rollers for AHSS generally should be smaller in diameter then those used for straightening mild steel, to provide a smaller radius around which to bend the material. This is because AHSS must be bent more severely in order to exceed its higher yield point.

Spacing: Work-roller center spacing must be closer for AHSS than for comparable mild-steel applications. Closer spacing means that more force is required to back-bend the material, requiring greater power for processing.

Support: Larger journal diameters with bigger radii and larger bearing capacity are needed to withstand the greater roll force and higher power required to straighten high-strength materials using closer roller center spacing.

Material: Higher-strength materials and special heat treatments must be employed to ensure rollers can withstand greater stresses for longer periods without experiencing fatigue failure.

Roll Depth Penetration: To effectively yield AHSS, the straightener must be designed so that the upper rolls have adequate travel between the lower fixed rolls. This can be 50 to 60 percent greater than what is required for conventional straighteners designed for mild steels.

Gears

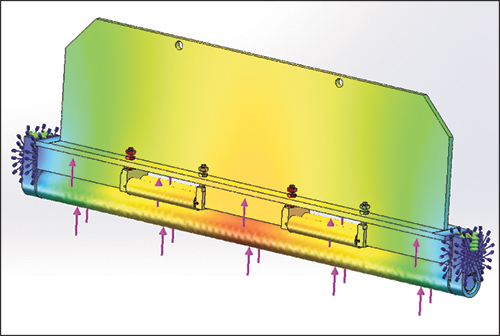

Upper straightener roll and backup assembly, showing stress and roll deflection from forces required to straighten AHSS.

Size: Wider gear faces are required, as well as outboard support of journals and idler shafts, to produce higher gear power ratings.

Positioning: Closer roll center spacing requires higher power transmission and results in a smaller gear-pitch radius, which reduces gear power ratings.

Material: Gears should be produced from heattreated high-strength materials to result in stronger gears.

System Rigidity

Backup Rollers: Given the smaller roll diameters and greater force requirements for straightening AHSS, work-roll deflection becomes a concern. Excessive work-roll deflection results in undesirable side effects such as material edge wave, increased journal stresses and premature gear failure. Backup rollers often are required at the center and intermediate positions of the straightener roll to prevent work-roll deflection.

Backup-Roller Support: Backup-roller support is vital to ensure the effectiveness of the backup rollers and prevent work-roll deflection when running AHSS. Backup-roller face width and the cross-section of the support structure are critical to providing proper work-roll support. Simply adding screw jacks to narrow cross bars will not provide the backup-roller support required to achieve a good result.

Journal Support: As mentioned, outboard support of the drive-gear journals is critical to providing the rigidity necessary to withstand the higher horsepower and torque requirements and improve the system gear ratings.

Force Delivery: Closer work-roller center spacing leaves less room for the work-roller force-delivery mechanism. Conventional off-the-shelf screw-jack designs cannot provide adequate force in this reduced space. Coe offers custom screw-jack modules that can be designed to fit the available space and deliver the higher forces required to effectively yield AHSS.