Diamond Grinding and Cleaning Wheels Last 100 Times Longer than Resin-Bonded Wheels

May 1, 2011Comments

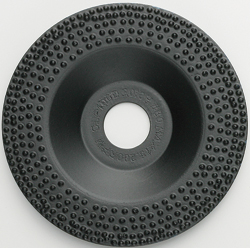

CS Unitec, Inc., Norwalk, CT, introduces Eco Brazing (EB) Diamond Cluster grinding and cleaning wheels, which reduce sparking to as little as one percent of that produced by resin-bonded wheels, say company officials. Use the discs to grind and clean steel, stainless steel, aluminum, fiberglass and other materials in general industrial applications, as well as in hazardous environments in oil, gas, nuclear, mining, marine and other industries. Minimal sparking decreases the fire hazard from sparks while increasing workpiece visibility, for accurate grinding and cutting.

CS Unitec, Inc., Norwalk, CT, introduces Eco Brazing (EB) Diamond Cluster grinding and cleaning wheels, which reduce sparking to as little as one percent of that produced by resin-bonded wheels, say company officials. Use the discs to grind and clean steel, stainless steel, aluminum, fiberglass and other materials in general industrial applications, as well as in hazardous environments in oil, gas, nuclear, mining, marine and other industries. Minimal sparking decreases the fire hazard from sparks while increasing workpiece visibility, for accurate grinding and cutting.The EB Cluster wheels are designed to remove paint, rust and epoxy on metal, as well as high material removal on fiberglass, composites and plastics without loading up as do traditional abrasives. Available in 80 grit and disc sizes 4-, 4.5-, 5-, 6- and 7-in. dia., the discs’ light weight allows for high-rotation grinding with portable angle grinders. Maximum speed ranges from 8400 to 15,200 RPM, depending on diameter.

CS Unitec, Inc.: 800/700-5919; www.csunitec.com

See also: CS Unitec, Inc.

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

FinishingAutomated Deburring and Chamfering

Friday, August 4, 2023