Titanium Processing

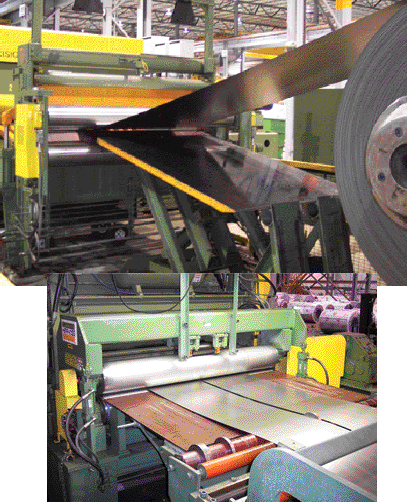

Noting again the need to expand its horizons beyond flat carbon-steel processing for automotive customers, Adamski describes recent growth into titanium-alloy coil processing. “We’re using the tension-leveler line to induce specific changes in the properties of the titanium alloys,” he says. “We can vary the

In 2005 the firm added an electrostatic oiler to the line, to improve its ability to deposit uniform, controlled coatings of oil or prelube on the coil stock. And, it recently switched to a new coating process used to refurbish the line’s bridle rolls, which has extended roll life from 9 to 15 months, translating into fewer outages for maintenance and increased line uptime.

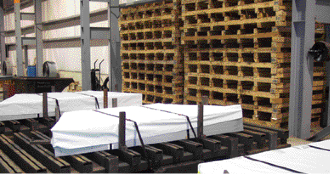

Rounding out its service offerings, Taylor has seen significant growth in work for its multiblanking line, primarily as local metalformers and service centers seek a more modern, accurate and cost-effective to replace their outdated blanking equipment. “We can provide a blanking service that is more cost-effective and that holds tighter dimensional tolerances,” says Adamski, “than the outdated blanking operations that many of the local companies run. We also in many cases can run larger coils and larger lot sizes, improving yield.

“We started the line working 4 hr./ day, 3 days/week,” he continues, “and today that line runs two full shifts a day, five days/week.”

Inspection Line, More Efficient Packaging Pay Dividends for Stampers

Taylor offers its value-added two-sided inspection line as a means for stampers to avoid having to cut defects out of a coil before loading the coil onto a press line, which results in the use of smaller coils and, therefore, more time-consuming coil changes. Instead, operators manning the inspection line place vinyl flags on the coil stock as it feeds through the line to denote surface flaws. That allows the stamper/customer to run a full coil and, when noting the defect flag, simply pull the part with the flag out of the parts bin.

“The stamper’s efficiency rises,” says Adamski, “and the prime yield of the material improves. We’ve seen customers improve throughput by 30 percent.”

In addition to helping customers improve yield, quality and JIT production efficiencies (via an online ordering system where customers can control delivery schedules to their liking), Adamski also explains how Taylor is helping customers reduce packaging costs.

“Packaging offers significant opportunities to control costs throughout the supply chain,” he says. “For example, some local customers, for which we might transport coils only five to 10 miles, in the past would require the coils to be fully paper wrapped, and perhaps elaborately banded. We’ve worked with many customers to show them that, since more coils tend to be used upon receipt, following a JIT schedule, there’s not as much need for full paper wraps. We can more simply band the coils, and then apply a loosely fit paper shroud over the coils rather than a full wrap. Not only is this significantly less expensive on the front end, but it also is simpler and more cost-effective at the back end when the customer has to dispose of the packaging materials.

“We also stress to customers that we can hold much tighter tolerances than they may realize,” Adamski adds, “so they might not need to order coils with an extra inch of width, which just turns into scrap. Instead, an extra half inch might suffice. This type of cooperation results in significant cost savings.” MF

View Glossary of Metalforming Terms

See also: Herr-Voss Stamco

Technologies: Coil and Sheet Handling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingServo Press Quartet Plus Zig Zag Feeds Yield Impressive Resu...

Brad Kuvin February 26, 2024

Four Before the Floor—Dallas Industries at FABTECH 2023

August 21, 2023

Video

Video