Renewable-Resource-Based Oils

Vegetable and many other types of renewable-resource-based soluble oils also have begun to make a targeted impact in the aluminum-forming market. In many cases they meet or exceed the performance of mineral-based soluble oils, while offering a non-petroleum-oil environmental advantage. The seed-oil base forms a strong boundary film when adsorbed onto the aluminum surface, preventing metal pick-up and allowing good sheetmetal flow.

Whether a mineral- or renewable-resource oil-based lubricant, new chlorine-free soluble oils now are pushing the envelope on aluminum-stamping applications. As an example, consider that for several years, an automotive-parts supplier formed parts from 0.055-in.-thick Type 5754 aluminum, with a 4-in. draw depth, using a chlorinated-paraffin straight oil. By switching recently to a chlorine-free soluble oil, diluted 4:1 with water, the stamper eliminated sporadic tearing and galling while reducing lubricant use and cost. Furthermore, it eliminated all cleaning and application issues.

|

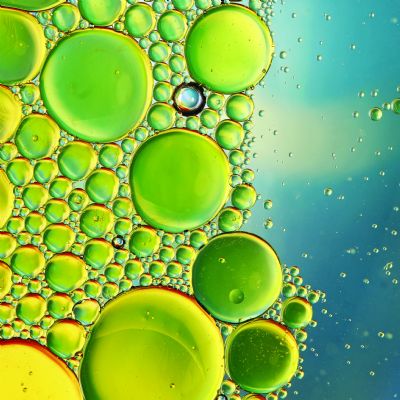

| Automotive-parts suppliers that typically deep-draw aluminum (shown here) using a chlorinated-paraffin straight oil can switch to a chlorine-free soluble oil and eliminate tearing and galling concerns while reducing lubricant use and cost. |

Now, don’t count out full-synthetic chemistry just yet. While older synthetics containing no petroleum or vegetable oil have lagged behind soluble oils, many newer products have risen to the occasion. Packed with newer polymer- and ester-additive technology, today’s full synthetics also prevent the pickup and drag normally experienced when forming aluminum.

Corrosion

As with most other substrates, compatibility with the stamping lubricant is of great concern with aluminum, especially when diluting the lubricant with water. Although ferrous staining and corrosion aren’t of concern here, metalformers will prefer to avoid any staining or pitting beyond the normal aluminum-oxide layer buildup.

Different alloys and finishes come with varying built-in corrosion resistance. For example, Types 5052 and 6061 aluminum offer excellent corrosion resistance and find use due to their good formability. However, higher-strength alloys such as Types 7075 and 2024 offer average or poor corrosion resistance.

When dealing with different alloys, certain lubricants are naturally passive while other lubricants must be buffered for pH and include additional corrosion inhibitors to prevent excessive attack on the substrate surface. Straight oils can offer very good corrosion inhibition due to the absence of water. Dry films also perform well, once any water carrier has evaporated. The extent of corrosion from water-soluble lubricants can vary depending on the pH of the water and the lubricant, as well as water quality and the additives in the product. Higher alkalinity can destroy the aluminum-oxide protective layer, which leads most water-soluble products to require corrosion inhibitors for proper protection.

To minimize the propensity for staining or corrosion in metalforming aluminum, metalformers should perform quick stain tests on the substrates. To carry out these tests, mix the water-soluble lubricant to the desired concentration, then cut an aluminum coupon and submerse it half-way into the diluted lubricant. After 24 hr. soaking at room temperature, inspect the coupon for staining and discoloration.

Post Processing

After forming, the presence of lubricant residue on the stamped aluminum parts can impact secondary processes such as cleaning, welding and painting. Depending on the severity of the forming, the remaining residue may be heavy or light, oily or sticky, thick or thin, and possibly pooled in corners or all over the part. Whatever the state, the stamper may have to plan for secondary processing to remove the residue.

In most cases with straight oils and dry films, the job calls for a solvent or high-alkaline water-based cleaner to remove the residue, as even the slightest amount of residue can impede welding and painting. For difficult forming operations requiring a straight oil, the stamper can opt for a lubricant with a special additive package to allow for quicker, simpler cleaning in an alkaline parts washer run at a relatively low temperature.

Soluble oils and synthetics with higher dilution ratios can leave minimal and dry-to-the-touch residues that, in many cases, can be welded through, depending on the composition and dilution required for forming. However, most residues, even if heavy, will wash off in a mild-alkaline cleaner or water rinse.

Regardless of the cleaning method selected, stampers must exercise caution. Perform tests on parts to ensure that the cleaning solution does not cause an adverse reaction, such as etching or staining of the workpiece material.

Health, Safety and Environmental

Aluminum use continues to expand, not just for its favorable strength-to-weight ratio, but also for its environmental advantages. So, why not apply this philosophy when selecting the optimal lubricant? We should advance beyond just looking for the best forming lubricant that performs well during secondary processing. Newer lubricants also can improve operator health and safety, and positively impact the environment.

EP agents continue to find use in fluids to help with carrying the friction load between the aluminum workpiece and the tooling materials. CLPs have been the talk of the industry lately, with the recent push by the EPA to ban medium- and long-chain CLPs based on data suggesting high bio-accumulation and persistency rates. While this debate continues, lubricant manufacturers have begun to look at EPA-approved and registered very-long-chain CLPs to diminish environmental bio-accumulation and persistency rates.

Other robust additives that reduce the reliance on traditional EP agents also have made headway into modern formulations, creating more eco-friendly stamping lubricants—not just environmentally friendly, but also friendly to users. With the GHS system in place now for a few years, safety datasheets reveal the potential hazards of a product with written warnings and pictograms.

A quick visual can tell a stamper how each lubricant stacks up and allow managers to make informed decisions regarding health and safety. If your lubricant now comes packaged with any pictograms, ask yourself if you would use the product in your personal life. If not, seek a better option that can significantly reduce your health, safety and environmental footprint. MF

View Glossary of Metalforming Terms

See also: Tower Metalworking Fluids

Technologies: Lubrication