Airbus Adds EB Machine to Print Large Titanium Structural Parts

February 10, 2017Comments

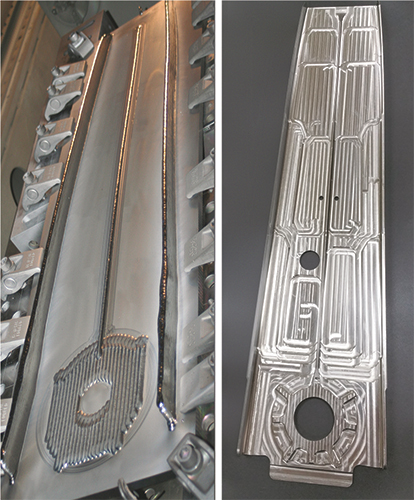

Sciaky, Inc., Chicago, IL, announced that Airbus planned to take delivery of an EBAM (electron-beam additive-manufacturing) 110 system (70- by 47- by 63-in. work envelope) in December 2016, to produce large titanium structural parts. Sciaky’s EBAM process combines computer-aided design, AM processing principles and an electron-beam heat source. A fully articulated, moving electron-beam gun deposits titanium via wire feedstock, layer by layer, until the part reaches near-net shape. From there, the part requires heattreatment and post-production machining.

Sciaky, Inc., Chicago, IL, announced that Airbus planned to take delivery of an EBAM (electron-beam additive-manufacturing) 110 system (70- by 47- by 63-in. work envelope) in December 2016, to produce large titanium structural parts. Sciaky’s EBAM process combines computer-aided design, AM processing principles and an electron-beam heat source. A fully articulated, moving electron-beam gun deposits titanium via wire feedstock, layer by layer, until the part reaches near-net shape. From there, the part requires heattreatment and post-production machining.

Sciaky tackles quality and control together in one step with its IRISS interlayer real-time imaging and sensing system, which can sense and digitally self-adjust deposition precisely and repeatably. This closed-loop control reportedly ensures consistent part geometry, mechanical properties, microstructure and composition.

Sciaky, Inc.: www.sciaky.com

See also: Sciaky Inc

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Additive Manufacturing

Additive ManufacturingAirbus and Oerlikon Sign Contract for Additive Manufacturing...

June 27, 2023

Cutting

CuttingAI in Manufacturing Makes Impressions at INTECH

Wednesday, April 17, 2024

Stamping Presses

Stamping PressesAP&T Collaborating with ArcelorMittal for Press Hardening Ap...

Wednesday, April 17, 2024