Brad Kuvin

Brad KuvinOEM Finds New Suppliers via Online Matchmaking

February 1, 2017Comments

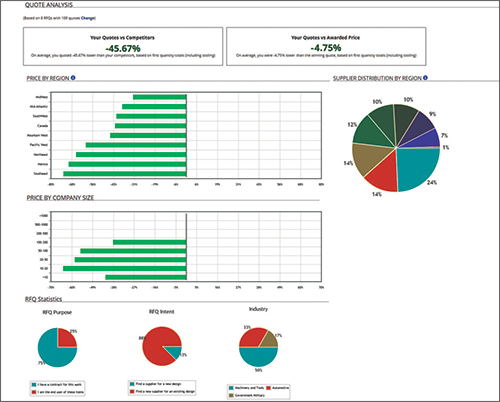

Since July 2015, Anchor Hocking process engineer Eric Goldman has been sourcing CNC-machined and fabricated-metal products using the online marketplace at MFG.com. Buying primarily maintenance items used for upkeep of the company’s glass-product (beverage- and ovenware, for example) mold lines, Goldman typically issues RFQs two to three times per month.

“We were paying $250 apiece for the relatively simple part,” Goldman says, “and I thought we could save some money by looking for a new supplier. I tried sourcing it on MFG.com, and was able to find a supplier in Ohio to provide the part for $40.”

Outsourcing Waterjet Cutting

Now Goldman is sourcing just about everything he needs through MFG.com, to keep the production lines running. “In addition to the 41 projects I’ve sourced online since July 2015,” he says, “we also use our inhouse machine shop when it has capacity. However, we do not have waterjet-cutting capacity inhouse, so anything that requires waterjet we source online rather than milling inhouse. For example, we often look for fabricated-metal parts cut from 3⁄4-in.-thick cold-rolled steel that cannot tolerate any heat deformation; waterjet is the process of choice.”

Of course, once he finds a new supplier that meets/exceeds expectations in terms of quality and delivery, Goldman considers that supplier ‘preferred’ and has no qualms about sending repeat orders back to that supplier, “provided they hold pricing or get close to it,” he says. “And we’ve had several re-orders; all new orders, though, get put out for quote.”

Noting that the 41 projects quoted on MFG.com accrued a total savings of $70,000, Goldman cites one particularly lucrative job as an example of the benefits realized from online sourcing: a machined stainless-steel part that had previously been purchased from an OEM as a cast part, for $125 apiece.

“We purchased 80 of these parts for $17.80 apiece through a supplier found on MFG.com,” he says. “That’s an $8500 savings just on this one order.”

Video

Video

Podcast

Podcast

Webinar

Webinar