Installed with Minimal Interruption

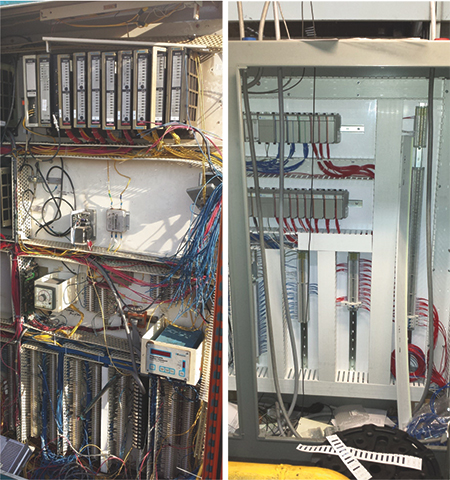

Ease of installation, with minimal press downtime and production interruption, played an important role in the Monterrey press upgrade. That press, says Turk, includes an eddy-current flywheel drive and magnetic clutch-brake system. “Integrating that drive with the new control was a challenge, but the PLC-based setup, with its flexibility and efficient wiring design, helped streamline the installation process.”

While the Milan press project opened Turk’s eyes to the benefits of open-architecture controls, compared to a proprietary control, the more recent project in Monterrey delivers even more benefits. Says Turk, “This technology just continues to accelerate in terms of delivering new features and benefits.”

Among those benefits is the use of Helm’s FirstMate WebVIew browser-based production-reporting software, generating reports on fault history and press-cell up- and downtime. Taking data from through-the-stroke tonnage-monitoring (Helm’s Loadgard package) sensors and Helm’s Mariner signature-analysis software, WebView generates real-time graphical waveforms for each production run and delivers them to remote PCs via Ethernet.

The Loadgard setup integrates force measurement with crank angle, providing detailed monitoring throughout each stroke. Users can set upper and lower limits and establish alarm setpoints, or even initiate press shutdown if necessary at any time during the machine cycle.

“Through-the-stroke tonnage monitoring and signature analysis,” Turk explains, “has really paid dividends. In particular, on deep-drawn parts we can quickly identify when a part tears and trigger a press shutdown before we generate a lot of scrap. We also can use the tonnage signatures to identify dull or broken punches and avoid making bad parts. Other benefits include downtime tracking, monitoring of snapthrough forces and better control of die wear.”

Challenging Applications Require Close Monitoring

|

|

|

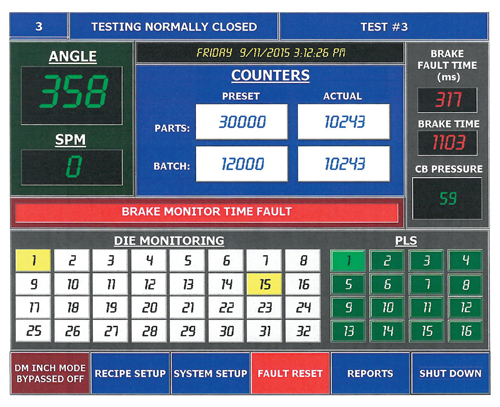

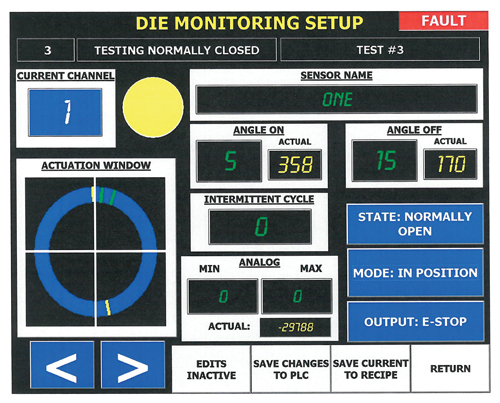

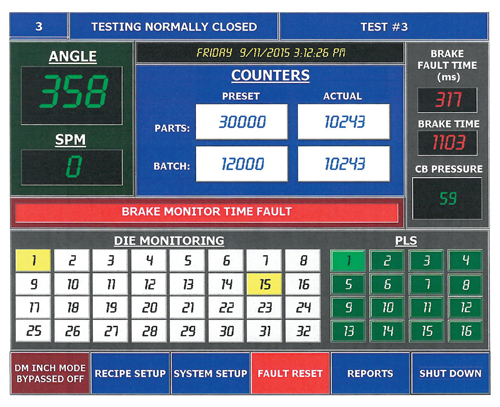

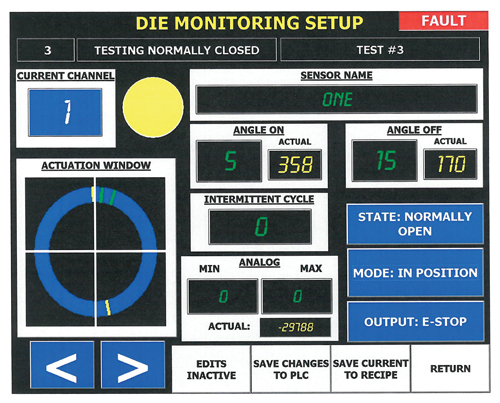

With the PLC-based control, human-machine interface (HMI) screens are completely customizable. Shown are the main screen (left) and the die-monitoring setup screen.

|

Dura and GAS plants manufacture a host of automotive products, including structural body products, seating systems and closure hinges. In addition, the Milan plant performs some rather dramatic deep-draw operations, including forming a door threshold 3-ft. long by 20-in. wide, with a 10-in.-deep cavity, drawn in one hit. That’s the type of part Turk refers to when explaining how through-stroke tonnage monitoring and signature analysis can pay off.

“We find the Loadgard tonnage monitor to be very intuitive and detailed in terms of the data it delivers,” Turk says. “We have it installed on nearly every press—the Milan plant houses 24 presses, from a 50-ton OBI to a 2000-ton transfer; Monterrey houses 14 presses, from 50- to 3000-ton capacity. We can store and recall signatures, and use it the data to generate SPC charts.”

Both control-upgrade projects also include Helm’s remote-access technical-support feature. “This allows us,” says Turk, “to provide Helm’s engineers with access to the controls, to expedite troubleshooting. They also can edit our programs, if needed, from remote locations. While we rarely have to use this feature, it eliminates the time and cost of travel for the Helm team, and it makes the troubleshooting process that much more efficient.”

Die Protection

On the press in Mexico, the control features 48 inputs for sensors. “If you run out of inputs,” says Turk, “you have to connect the sensors in series. We do not want to do that because it makes it harder to trace problems if a sensor fault occurs. So, we want to isolate the sensors, especially on a press that large, that includes automation. We have cam drivers on that press, and we want to monitor whether they are in or out, and whether a part is sitting in the die correctly, on each end. That means we can have six sensors in one station—cam-in and cam-out on each end, and part-in-place on each end.

“We also rely on the press control for brake monitoring,” he continues, “a very important safety feature. We can track the stopping time of the press, which lets the operator know if he needs to adjust the brakes.”

An added safety feature: use of programmable safety relays. This, according to Helm, enables control of multiple light-curtain functions including barrier guarding and e-stops.

Lastly, as temperature in the plant can impact press performance and reliability, Turk equipped the control setup to monitor operating temperature and ensure that bearing points remain adequately lubricated.

“Prior to the control upgrade, we had downtime incidences caused by excess temperature,” he says. “Now we use the press control to monitor temperature, ensuring that operators pay close attention to press lubrication; downtime has practically been eliminated.” MF

See also: Helm Instrument Co., Inc., Blow Press Limited

Technologies: Pressroom Automation, Sensing/Electronics/IOT, Stamping Presses

Brad Kuvin

Brad Kuvin