Improved Software for Tool Design and Build

October 1, 2017Comments

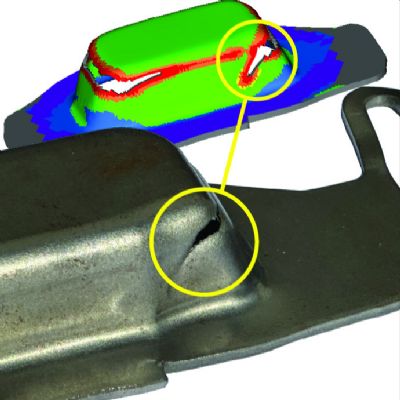

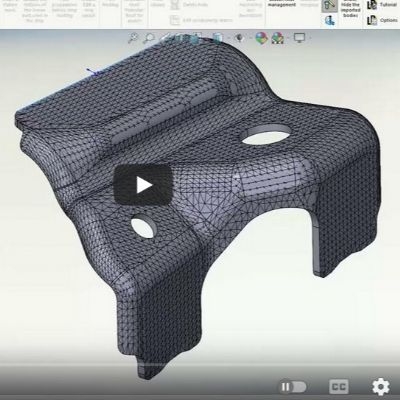

Tebis America, Troy, MI, specializing in CAD/CAM systems for design and manufacturing services for the tool and die industries, announced release 4 of its Version 4.0 software. With the release, Tebis software creates area curves during part comparison to enable better detection and limitation of modified areas. Design measures can thus be quickly implemented or new NC programs can be quickly calculated for modified areas. The new function creates non-overlapping shifted surfaces from any curves at defined angles. All overlaps within parts that would result especially at sharp edges and small radii of curvature are automatically filtered out and smoothed. This is ideal for those working with trim steel and trim-line surfaces in draw-die manufacturing. The lengths and angles of surfaces are interactively adjusted using drag arrows.

Tebis America, Troy, MI, specializing in CAD/CAM systems for design and manufacturing services for the tool and die industries, announced release 4 of its Version 4.0 software. With the release, Tebis software creates area curves during part comparison to enable better detection and limitation of modified areas. Design measures can thus be quickly implemented or new NC programs can be quickly calculated for modified areas. The new function creates non-overlapping shifted surfaces from any curves at defined angles. All overlaps within parts that would result especially at sharp edges and small radii of curvature are automatically filtered out and smoothed. This is ideal for those working with trim steel and trim-line surfaces in draw-die manufacturing. The lengths and angles of surfaces are interactively adjusted using drag arrows.

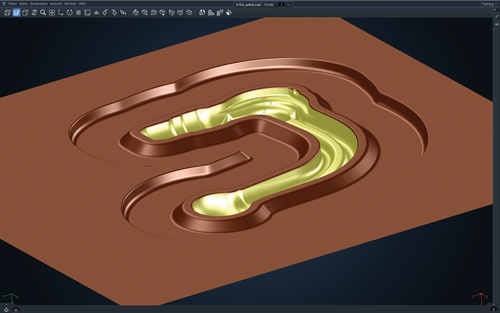

In addition, parts now are automatically morphed together with complex trimming curves in surface morphing. The geometry of the original curves is fully retained and color properties are transferred in a ratio of 1:1. Curves are included in surface morphing. In draw-die manufacturing, if active surfaces must be morphed to compensate for springback of the sheet, all trimming curves are morphed to yield the geometries for a correctly trimmed sheetmetal part in a single step.

Also, deep-hole drilling in the CAM area is better-oriented to support automated calculation and machining. The software also includes a new tool type with an extended set of cutting data and special speeds, feed rates, cooling types and depth sections needed for deep-hole drilling. These values are managed separately for each individual tool.

The software also offers a host of other upgrades and additions.

www.tebis.com

See also: Tebis America, Inc.

Webinar

Webinar