|

Big Benefits for Knapheide from Automated Nesting

|

| This new fiber-laser cutting machine is one of many machines at Knapheide that employ automated nesting software to more efficiently produce truck parts. |

Since 1848, the Knapheide Manufacturing Co. has helped move America—first as a wagon builder, then as a supplier of truck bodies. Today, the company’s main manufacturing operation in Quincy, IL, occupies 480,000 sq. ft., with 124 of the plant’s 754 employees performing fabrication-related duties across three shifts. Shop-floor equipment includes CNC shears, plasma and laser cutters, CNC turret punch presses, and press brakes and rollformers, in addition to automated steel-processing cells. Since 1999, Knapheide has used nesting software from Optimation, Blue Springs, MO, building up to where, these days, most of the cutting and punching machines employ the software for customized nesting.

“We are a big job shop and process several low-volume orders all day, so we have a constant flow of orders dropped into our equipment,” explains Greg Schutte, director of fabrication and material handling at Knapheide. “As a result we don’t nest very far ahead, not more than an hour on any of the machines. And we constantly are building nests.”

Knapheide has gone through several updates and new versions of the Optimation nesting software, including the newest product, Axiom VE. The software pipelines with the fabricator’s MRP system to constantly address new orders or changes, and makes nesting decisions on the fly, according to Knapheide officials.

Optimation has custom-designed the software in tandem with the fabricator, using Knapheide employees’ expertise and experience to make automated nesting as efficient and accurate as possible.

“The nests here are built on the shop floor, at the machines,” says Noah Caldwell, Knapheide NC programmer, “as opposed to traditional nesting that occurs in an office setting. We customize our software to stay within a number of decision ranges, such as material gauge, quantity, length, width, etc. The software is highly customizable, allowing us to set up nesting to run automatically and set up the equipment to immediately run those nests. Doing so helps us maintain short lead times and operate just in time (JIT).”

Order quantities at Knapheide average less than 10 pieces with a “huge amount” of job numbers, so the ability to automatically nest is critical to maintaining JIT status.

“We don’t static-nest anything because we make so many custom, low-volume parts,” Schutte says. “We perform dynamic nests where a 60 by 120-in. sheet might have 50 different components with various quantities within that nest. We use parts in assembly operations either the same or the next day, so automated nesting (working in tandem with highly automated loading and unloading) has removed a lot of the queue time between operations.”

“We have seen continuous improvement in our materials utilization,” adds Caldwell, “which is a big driver for using the nesting software.” Now spending about 20 percent of his time on programming, Caldwell is able to take the time to leverage his CNC expertise in other areas, such as to coach various manufacturing teams at Knapheide through entire job setups and runs. The company, with savings on the nesting end, can tap the expertise of employees throughout all of its operations. The result is a solidified bond with customers.

“Using this nesting software has allowed Knapheide Manufacturing to focus more on our customers and their needs,” says Schutte. The time normally spent on nesting, material utilization and programming is used instead on collaboration and continuously improving within the company. Our focus is to never settle, and the software has proven to be a key component in our fabrication success.”

|

But as requirements constantly change, especially in job shops with many part numbers, repeated nests become inefficient. A part may be damaged and must be remade. Or, the schedule changes because a purchased part is not delivered on time, machines break down… In short, the shop floor is a constantly changing environment, and any series of nests that extend more than one machine cycle into the future can produce the wrong parts.

An intelligent nesting system considers all of the current conditions to produce optimal nests for the next machine cycle, then stops and waits for the next available machine to request a nest. During that wait time, unplanned events, such as those noted above, occur. So when the next machine requests a nest, any new criterion is included in the new optimal solution for the next machine cycle. A new part is scheduled and produced during the next machine cycle; the schedule changes, so all available resources are utilized to make the right parts to support the change.

Savings in Manpower, Time and Material Utilization: An Example

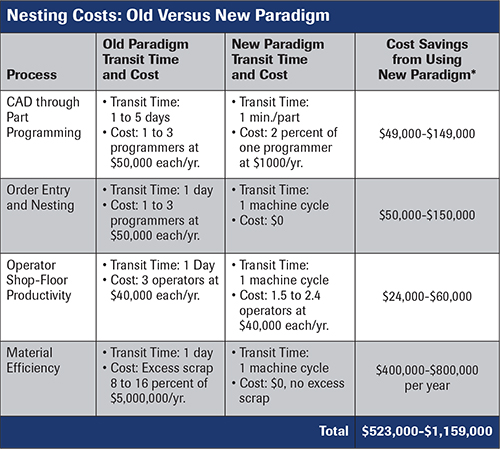

A value stream can show a number of different variables that express time and value. For now, let’s be concerned with savings and transit time for each operation. The accompanying table, Nesting Costs: Old Versus New Paradigm, compares the new and old paradigm for a company using three machines and accumulating $5,000,000 in nested raw-material costs each year.

To estimate possible savings in order entry and nesting time, determine the number of employees used for these functions each day. Savings will be 100 percent of these costs, as order entry and nesting becomes completely automated.

It is important to note that employees freed from traditional nesting tasks will be used, at least in part, for continuous improvement. Additional savings on their salaries will result from benefits of cost improvements that they may implement. In these estimates, it is assumed that continuous improvements will reduce annual costs by a dollar amount greater than the salaries. Therefore, savings shown are the full salaries.

The elapsed time from availability of new CAD parts to completed part programs includes not only programming time, but also the wait time from release until a part is programmed. For example, 100 parts released at the beginning of a day and available to be nested by the morning of the next day results in a transit time of one day. The same method can be used for nesting transit time—the elapsed time from when parts are available to be nested until they are run on the shop floor.

Speed, or reduced transit time, allows for production of only the parts needed next, which reduces work-in-process (WIP) inventory. In slower shops, unplanned events create further delays and increase costs. Rapid-transit shops respond to unplanned events in the next machine cycle, meaning no additional delays and chaos caused by unplanned events. Take, for instance, a defective part that must be remade. Significant delays in responding to this hot part will compound problems. The press brake used to bend the parts may have to move on to a different job with a new setup, and then incur an additional setup later on to remake the hot part. Responding quickly to unplanned events ensures reduced setup time, smooth flow, less WIP inventory and on-time delivery. MF

Article adapted from a white paper, 5th Generation Rapid Transit Time Nesting Systems, provided by Optimation, Blue Springs, MO; tel. 877/827-2100, www.optimation.com.

See also: Optimation Software Products

Technologies: Software