Stuart Keeler

Stuart KeelerEvaluating Stretching Capacity

April 1, 2016Comments

Mild and high-strength steels are available with many levels of strength and formability. Metalformers across the world use different properties to specify and order their steel, yield and tensile strength being the most common. Press shops often receive certifications with their incoming coils; these only specify composition, and lack information about formability.

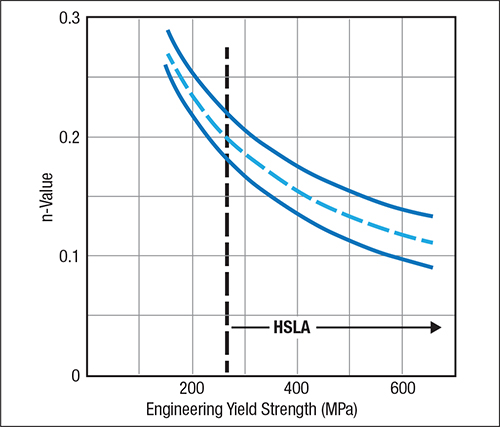

Fig. 1—Graph showing interaction between yield stress and n-value. These data are not applicable to the new advanced high-strength steels.

Stamping of metal parts requires property information that exceeds the conventional yield and tensile strengths. Two additional key properties, workhardening exponent (n-value) and the forming-limit diagram (FLD), often are not included with the shipping information. And, not all press shops have the test equipment needed to obtain their own data.

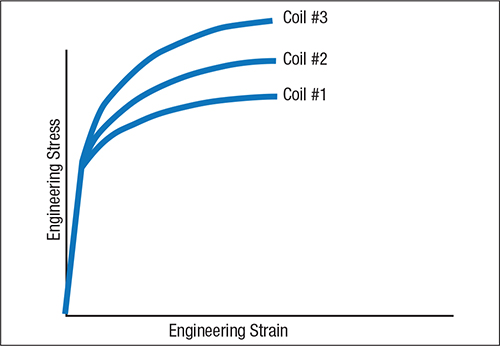

Fortunately, some general properties for steels can be found, while other information can be estimated. The n-value for mild and high-strength steels tends to remain constant over the entire deformation life of the steel. If the yield strength is known, the n-value can be obtained from the curve in Fig. 1. As strength increases, n-value decreases; metallurgical methods that strengthen the steel also restrict its stretchability, by reducing the n-value. Plotting the n-values from different coils of steel can provide the relative formability information that metalformers need.

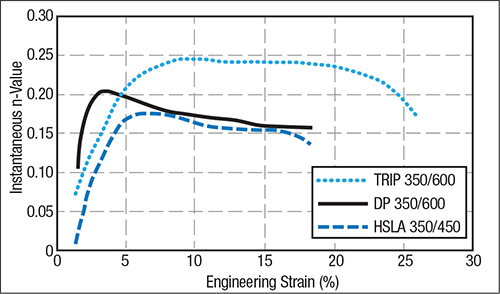

However, metalformers cannot use this curve to evaluate advanced high-strength steels (AHSS). The properties of these steels change during deformation, requiring the use of instantaneous n-values (Fig. 2). Here we show instantaneous n-values for three different AHSS grades with the same yield strength. The TRIP steel reaches an n-value of 0.25, the same as a vacuum-degassed interstitial-free mild steel, with a yield strength half that of the TRIP steel.

Fig. 2—Three steels with the same yield strength (350 MPa/50 ksi) have vastly different instantaneous n-values and stretchability capacities. Courtesy of WorldAutoSteel—AHSS Application Guidelines—Ver. 5.0

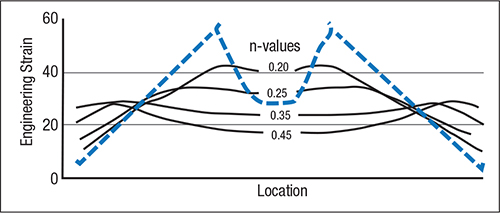

Another indicator of high n-value is total elongation. Under the same test conditions (Fig. 2), the sample with the largest total elongation also has the highest n-value and stretch capacity. Similarly, the FLD also depends greatly on n-value. Fig. 2 reveals that the TRIP steel has the highest FLC0 and the largest safe zone for stretching.

Video

Video