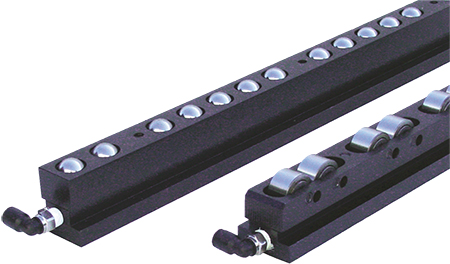

Hydraulic Roller Bars

Hilma Div. Of Carr Lane Roemheld Mfg. Co., Fenton, MO, offers smooth die movement into and out of presses, via its hydraulic roller bars. Used in pairs or sets, they lift the die and provide a roller surface to easily roll the die in place during the die-change process. For use in standard 11⁄16-in. or ASA T-slots, the bar’s hydraulically operated supporting rollers allow simple movement in line with the bar.

Hilma Div. Of Carr Lane Roemheld Mfg. Co., Fenton, MO, offers smooth die movement into and out of presses, via its hydraulic roller bars. Used in pairs or sets, they lift the die and provide a roller surface to easily roll the die in place during the die-change process. For use in standard 11⁄16-in. or ASA T-slots, the bar’s hydraulically operated supporting rollers allow simple movement in line with the bar.

The rollers, available in four sizes, can be positioned for front-to-back or left-to-right movement. Maximum operating pressure is 1740 psi.

www.clrh.com

Customized Die-Change Systems

With inhouse engineering expertise, Serapid, Sterling Heights, MI, has the ability to design solutions for nearly any load-transfer application, according to company officials. The company makes use of rigid-chain technology, employing electromechanical lift power as an alternative to hydraulics. The environmentally friendly technology (no hydraulic oil) has been used for lifts to 300 tons, while reportedly using less power and energy when compared to hydraulics. The addition of regenerative drives offers the possibility for even greater energy savings.

The company offers three types of die carts (all customizable) that run on rails embedded in the floor of a facility, a safe system that allows for accurate, repeatable positioning.

Also offered: custom-engineered domino-style die-change systems, ideal for serving an entire line of automated presses. Such a system first brings die carts carrying new dies into position in front of their respective presses, with one empty cart to the rear of the last press. Carts and press bolsters are then aligned, and new dies are pushed into their presses, with the old dies pushed onto the carts on the rear of these presses, in a domino effect. The carts move back again and bring the old dies to storage. This operation is controlled manually by the operator, with a pendant device.

www.serapid.com

Hydraulic Control Units Assist in QDC Efforts

Included in its QDC portfolio, PFA Inc., Germantown, WI, offers high-pressure hydraulic control units, powered with commonly available air pressure and made in a variety of configurations to optimize all QDC applications. For example, locking clamps are hydraulically actuated and then mechanically locked during press operations. They must be re-pressurized in order for the mechanical locks to be released. A hydraulic pressure booster button makes unlocking a simple process. Also, hydraulic die-lifter rails provide exceptional lift capacity, but must be lowered prior to clamping. The addition of a hydraulic pressure-relief valve helps protect the rails in the event that dies are clamped before rails are lowered.

www.pfa-inc.com

Pre-Rollers in Various Styles

Pre-rollers simplify the process of pulling out and pushing in dies, allowing the use of a forklift or crane to remove and load the die while minimizing the risk of damage to the dies or the press.

Mounted as a set, pre-rollers from EAS Mold & Die Change System Inc., Menomonee Falls, WI, are equipped with hardened-steel-surface needle roller bearings to offer a high load capacity, and are available for varying die weights and sizes. Die stoppers at the end of the pre-roller prevent the die from rolling off while allowing simple loading of the die onto the pre-rollers. With mounting blocks added, the pre-rollers can be used on several presses. Fixed pre-rollers from EAS offer greater lengths and higher load capacities, and these units can be moved, such as into storage, via adjustable supports.

Pre-rollers also can include swivels to turn the units away from the front of the press, or they can be motorized, thus serving as economical alternatives to die-change tables.

www.easchangesystems.com

20-Ton-Capacity Pneumatic-Die-Lifting System

The patented Tee-Lift pneumatic die-lifting system from Wardcraft Conveyor, Spring Arbor, MI, can work with dies weighting to 20 tons. Comprised of steel rails custom-designed to fit into specific applications, the system includes spun polyester/TPU-lined air bags positioned below the rails in designated T-slots. When shop air is injected into the air bags, the rails are pneumatically lifted to the shoulder stop in the T-slots. Crowned rollers, set into the rails, are subsequently raised 1⁄8 in. above the bolster surface, lifting the die in the process.

When the original die is removed and a new die is positioned on the Tee-Lift, the air is released, bringing the rollers and rails below the bolster surface and leaving the die securely in place. The weight of a die will determine whether the die can be positioned manually or if mechanical assistance is required for loading/unloading.

www.wardcraftconveyor.com MF

See also: Wardcraft Conveyor & Quick Die Change, Pacesetter Systems, Serapid, Inc., PFA, Inc., ROEMHELD North America

Technologies: Tooling

Lou Kren

Lou Kren Air Glide heavy-duty pneumatic die lifters from Pacesetter Systems, Inc., Valencia, CA, are available with ball bearings for multidirectional movement or cylindrical bearings for inline movement. The die lifters require only 40 lb. of force to move a typical 2,000-lb. die, according to company officials, reducing strain on employees while also reducing die-changeout time.

Air Glide heavy-duty pneumatic die lifters from Pacesetter Systems, Inc., Valencia, CA, are available with ball bearings for multidirectional movement or cylindrical bearings for inline movement. The die lifters require only 40 lb. of force to move a typical 2,000-lb. die, according to company officials, reducing strain on employees while also reducing die-changeout time.