Stuart Keeler

Stuart KeelerNew Technology Means Back to School

May 1, 2015Comments

|

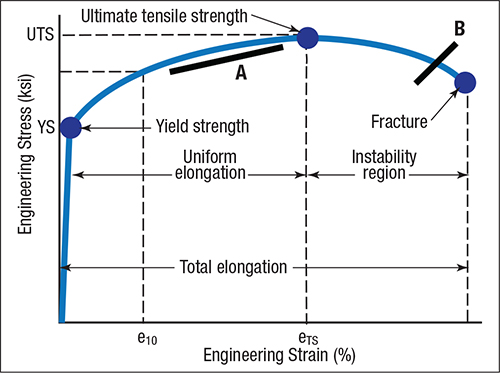

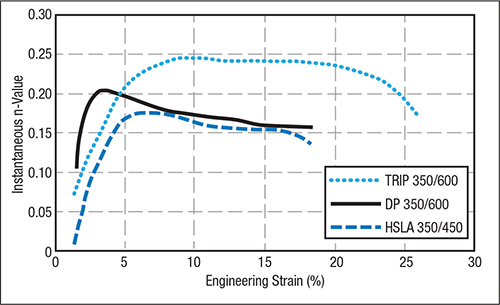

| Fig. 1—Many stampers only use yield strength, ultimate tensile strength and fracture information. However, the important stretchability data are contained in Zones A and B. |

New metalforming technology developments surround us—growing perhaps at the fastest pace ever. Examples include completely new steels with significant increases in strength, servo presses and 3D printing. To remain competitive, manufacturers working with sheetmetal must strive to keep up. Here we focus on the most important mechanical property of steel that controls stretchability—workhardening exponent, or n-value.

In days gone by, a blacksmith would assess stretchability of a sheetmetal blank by using a strong pair of grips to grab the corner of the blank and bend it. The force required provided a measure of the material’s strength, and stronger meant less stretchability and formability. Unfortunately, this test was limited to thinner sheets, and the results were not numerical but mainly estimations and emotions.

|

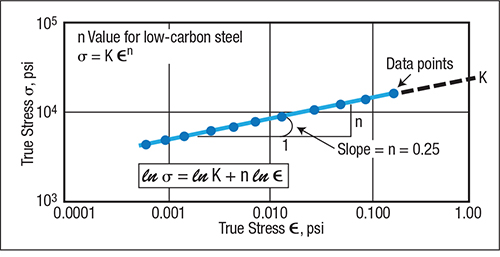

| Fig. 2—Plotting datapoints from Zone A in Fig. 1 allow computation of the n-value. |

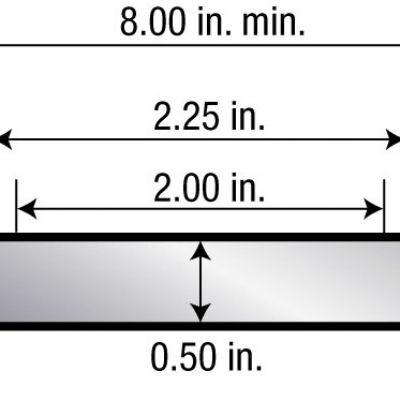

A major breakthrough occurred with the development of the tensile-test machine and the use of prepared test samples. The output of this machine was a stress-strain curve that provided three major properties: yield strength, tensile strength and total elongation (Fig. 1). Today many properties of different types and grades of sheetmetal can be determined. Other research evaluated the requirements needed to form specific shapes in stampings. Matching the workpiece material to the die became numerical instead of theoretical.

As noted, an extremely important material property that affects stretchability is n-value, determined from plotting data from Zone A in Fig. 1 is according to a specific equation on log-log graph paper (Fig. 2). This graph shows the n-value as the slope of the curve. The 0.25 value indicates a vacuum-degassed interstitial-free (VD-IF) steel with excellent stretchability. Although n-values were available by 1940, mass utilization was delayed until the 1970s. Even today some press shops still do not utilize this valuable property.

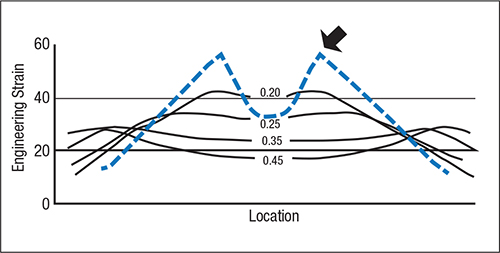

High n-values reduce or prevent localized strain (stretch) gradients from growing to failure. The hemispherical-punch stretch test (Fig. 3) illustrates how high n-values reduce peak strains and redistribute deformation during stretching. Steels for the various n-values:

Video

Video