Brad Kuvin

Brad KuvinBig Data Promises to Pay Big Dividends

October 1, 2015Comments

Earlier this year, Chicagoland metal finisher SWD Inc. made a significant capital investment that company president Rick Delawder strongly believes provides the company with a strong competitive advantage. New data mining and analysis software from Advizor Solutions, Downers Grove, IL, now has the firm’s management team “looking at things way differently than our competition,” Delawder says.

Decision-making in an Order-Intensive Environment

SWD operates a 165,000-sq.-ft. facility in Addison, IL, where more than 150 employees process hundreds of orders per day. Among its process offerings, performed for manufacturers of fasteners, metal stampings, springs and other metal parts, are computer-controlled plating, dip-spin coating (a non-chrome corrosion-protection process) and fastener sorting. Customers include automotive and agricultural-equipment OEMs, each with their own unique coating specifications but all with similar quality requirements. That is, as close to zero defects as possible, a directive that pushes Delawder to drive continuous improvement throughout the company. And it’s that drive that ultimately led him to invest in the Advizor software.

“We often have more than 1000 active orders being managed at any one time,” says Delawder. “We needed a tool to open up new ways to see what’s happening on the floor, discover inefficiencies and optimize performance. In that way, the software is a continuous-improvement tool at its best.”

Delawder’s ultimate inspiration to find a way to dig deeper into the firm’s data vaults came from reading the book, “The Everything Store: Jeff Bezos and the Age of Amazon.”

“I read that,” he shares, “to understand how ‘big data’ and data mining can become critical success factors, and how digging deeper into the data, using specialized tools provided by Advizor Solutions, creates opportunities for manufacturers to improve their performance.”

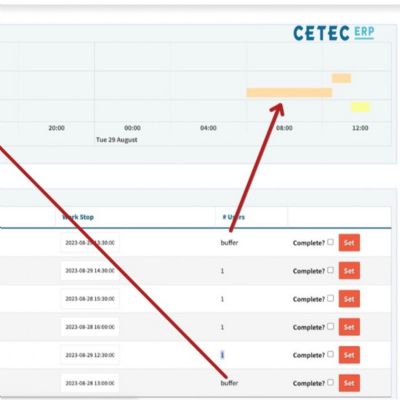

One way this plays out, Delawder explains, is when the data pulled out and analyzed by Advizor might identify a repeat job that generates more profit one day than it does on another, or that runs more quickly one day than it does on another. Many jobs, in fact, run through multiple processes, and Advizor, by querying the databases and providing specific reports, also can help managers see where specific job runs are more efficient than others. A job, Delawder explains, could comprise one huge lot that runs through the finishing department, and then separates into two or three loads through the dip-spin department and then into several lots through the sorting department.

“These deep and specific insights into our operations help us zone in on opportunities for improvement,” Delawder says. “And they often can help with capacity planning and even guide us as we look to make our next capital-equipment investments.”

Customer Communication on a New, Raised Level

…by attending a free 1-hr. webinar on Thursday, October 15, 2-3 p.m. Hosted by MetalForming magazine, the webinar will educate and inform attendees on the capabilities of the software, and how its patented data-visualization capabilities propel manufacturers to new levels of business performance. Learn more and register to attend by visiting www.metalformingmagazine.com, or https://attendee.gotowebinar.com/register/ 2290457911931642881.

Advizor’s software, in addition to supporting shop-floor processes, scheduling and production planning, also supports customer communication and insights.

“We can create very specialized and detailed reports for customers,” says Delawder, “to show them exactly how we’ve been performing for them in terms of delivery dates, quality and other performance measures. Having the data to back up those performance reports enhances our customer relationships greatly when compared to merely relying on intuition—ours and our customers’.

“We can build in specific rules,” he continues, “that help us develop minimum invoice amounts for jobs based on the number of parts or by order weight, for example. This prevents inaccurate quotes and invoices. We also can send the Advizor date-mining routines deep into the databases to identify order trends for specific customers.” MF

See also: Advizor Solutions, Inc.

Technologies: Management