Peter Ulintz

Peter UlintzUnderstanding Formability Results

September 1, 2014Comments

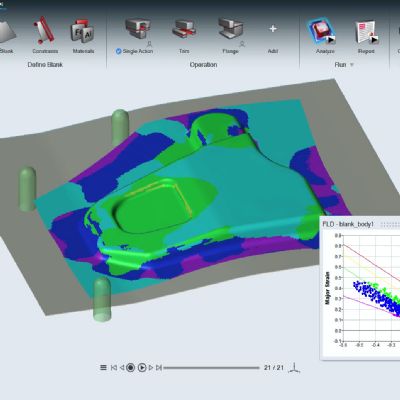

Process-modeling software makes science-based manufacturing knowledge readily available early in the product-design and process-quotation phases. Modeling techniques routinely employed for metal stamping often are referred to as metalforming simulation or virtual stamping. Designers select from two basic types of solvers (methods) for process modeling: one-step solvers and incremental solvers, each having unique advantages and disadvantages.

One-step solvers, generally used during product development, process planning and quoting, primarily find use for assessing manufacturing feasibility. Incremental codes are used as final validation for completely defined product and process designs.

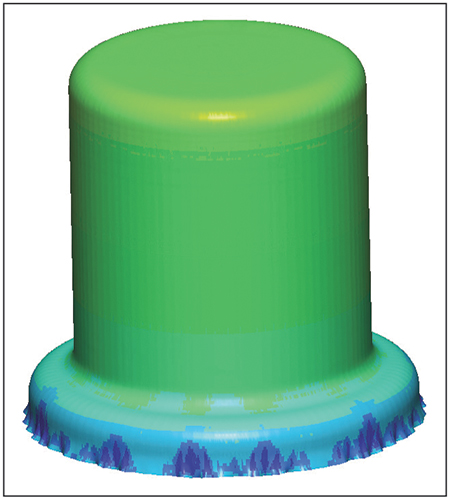

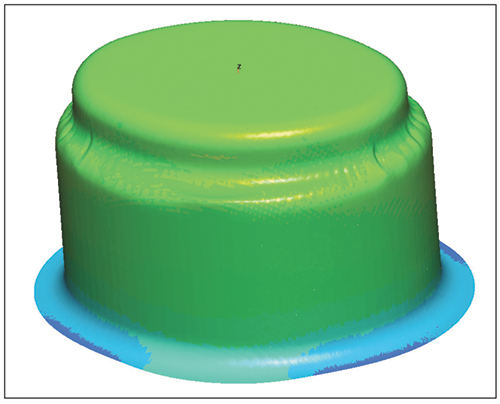

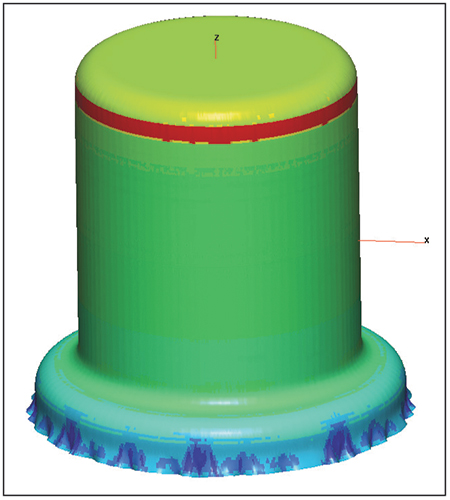

Fig. 1—Puckering in a safe zone

Capability and Limitations

Estimating engineers can take advantage of blank-prediction software, a derivative of the one-step method that provides users with a fast and accurate method for developing blank shapes, blank nesting and cost estimating. These solvers can capture sheetmetal stretching and compression that normally occurs during the forming process, but which may not easily be accounted for using classical length-of-line measurements or unfolding software.

The primary disadvantage of a one-step solver is that it works only for single-step forming operations. Due to simplifying assumptions, one-step codes compromise accuracy for the sake of time. But the advantage is that engineers can evaluate numerous what-if scenarios, in a matter of minutes, to help identify important process parameters. Because of their speed and minimal input data, one-step codes routinely find use for evaluating product designs and for establishing feasible processing methods when little or no process data is available.

Unlike one-step codes, incremental codes are not restricted to a single forming operation. Modeling all of the process steps allows strains generated in previous forming operations to be carried over to subsequent operations. This is important because strain history plays an important role in formability accuracy and springback prediction.

The advantage of incremental solvers is that they can be used to conduct a series of virtual die tryouts using specific blank shapes and material properties with production-intent tooling geometry. In addition to formability assessment, designers use incremental solvers to conduct trim-line optimization, springback analysis and process-sensitivity studies.

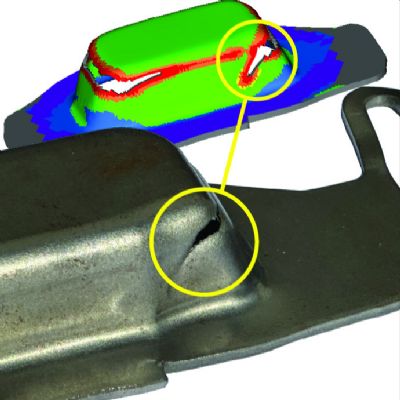

Fig. 2—Failure using material thickness for clearance

On the other hand, incremental solvers inherently are more sophisticated, requiring longer learning curves, more preprocessing steps and much longer computing time compared to one-step methods. Depending on process complexity and available computing power, this can take as long as a day or two, or as little as a few hours.

Understanding the capabilities and limitations of simulation software is necessary in order to accurately interpret formability results.