Electronics Manufacturer Adds High-Speed Press Line with In-Die Welding

September 1, 2013Comments

The 27-yr.-old Mexican manufacturing plant of Italian electrical-equipment manufacturer Bticino, in Queretaro, manufactures more than 100 different product families. With more than 600 employees, the plant is “constantly innovating and introducing new designs,” says engineering manager Daniel Vega. To keep up with production demands and manufacture products with newly added functions, the company dedicates at least five percent of its budget to research and development.

The 27-yr.-old Mexican manufacturing plant of Italian electrical-equipment manufacturer Bticino, in Queretaro, manufactures more than 100 different product families. With more than 600 employees, the plant is “constantly innovating and introducing new designs,” says engineering manager Daniel Vega. To keep up with production demands and manufacture products with newly added functions, the company dedicates at least five percent of its budget to research and development.

“We are als upgrading our manufacturing processes to keep pace with the new-product designs,” Vega says.

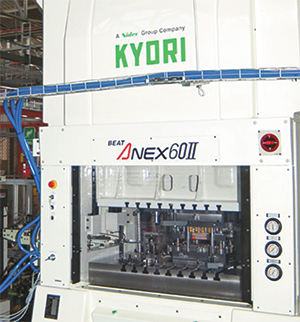

The latest such upgrade: a 600-kN Kyori ANEX 60II mechanical press outfitted with a Kyori GX gripper-feed unit—ideal for feeding parts such as narrow-pitch connectors—and two Bihler in-die welding units. Bticino employs the press line, installed in February 2013, to stamp complex connectors at 250 strokes/min. Key press specifications: 300-mm shut height and 80-mm shut-height adjustment; 1100- by 600-mm bolster area; 840- by 120-mm bed opening.

Kyori ANEX presses, sold in North and South America, as well as in Europe, by Nidec Minster Corp., Minster, OH, feature knuckle-link slide motion, cast-iron frame construction, combination air friction clutch and brake unit, continuous press lubrication and electronic stroke-position indicator.

Watch the press run during a 1-min. video; just search YouTube for “Kyori at Bticino.”

Nidec Minster Corp.: 419/628-2331; www.minster.com

See also: Nidec Press & Automation

Technologies: Stamping Presses, Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Stamping Presses

Stamping PressesIncreasing Press Speed and (In)Efficiency

Peter Ulintz Thursday, March 30, 2023