Controls Resuscitation

Called on to rescue TMS from its press-control crisis and restore order to its lean processes: Toledo Integrated Systems, Toledo, OH. In 2010, Toledo Integrated replaced the existing operator screens and PLC controls on both of TMS’s hydraulic presses, including all distributed I/O. Out with the old, in with the new—for starters, Toledo Integrated installed a Siemens S7-300F-series failsafe processor in each control in place of the existing redundant PLCs. Toledo Integrated product manager John Eby explains:

|

| Among TMS’s standard product lines are these heavy-duty waste receptacles, fabricated from 16-gauge stainless steel, shown here awaiting finishing in a robotic cell. |

“While safe PLCs have been available for several years, we’ve not seen them implemented in pressrooms until recently, as their price has dropped significantly to make them more affordable for retrofit projects such as those at TMS. One safe processor can internally provide the same level of redundancy and safety as dual PLCs, providing a simpler and cleaner solution. There’s less wiring, less cabinet space required and fewer maintenance concerns.”

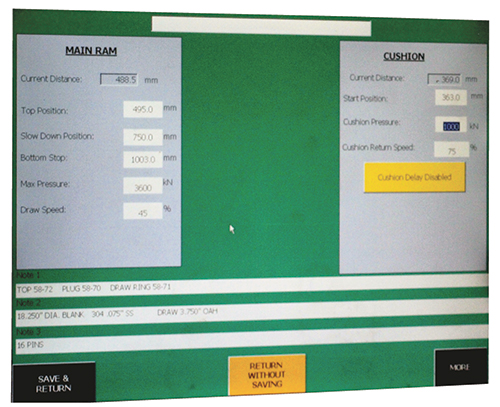

Out on the shop floor, we spoke with press operator Dan Tenney, a 29-yr. TMS veteran, about the new HMI interface—a 15-in. color-screen industrial PC loaded with software customized by Toledo Integrated to manage the complex and often finicky deep-draw process. Tenney and his fellow press operators now are called on, thanks to the move to cellular manufacturing, to run as many as five machines in a cell, not just the stamping press. “That’s why the simpler, more efficient press control makes my job that much easier,” says Tenney.

Customized Application Software

To breathe new life into the TMS hydraulic-press duo—and in fact take them to levels of productivity and reliability—Toledo Integrated outfitted each with a Siemens Panel PC running Siemens WinCC Flexible application software. Eby and his team customized the software to include all preexisting functions, along with enhanced operator-friendly screen layouts and diagnostics.

“The new touchscreen not only is user-friendly,” Tenney says, “but now all of the job parameters are displayed on one screen—ram position, pressure, etc. Before, we had to click through several screens to obtain all of the data needed to monitor the process and make adjustments—and adjustments are a fact of life when deep drawing on a hydraulic press. It’s not a set-it-and-forget-it process.”

The presses each comprise four hydraulic cylinders—two downward acting and two upward acting. Tenney and his peers can program each cylinder independently with regard to speed, stroke length and force to adjust blankholder force and develop reverse-draw and redraw routines.

“Programming is remarkably faster and simpler,” Tenney continues. “Programming a new job used to take, on average, 30 to 45 minutes. Now, with easier access to screens and data, and the ability to repurpose parameter recipes from previous jobs to plug into new programs, we can program new jobs in 15 min. or less. Then, as programs run inproduction, we can make adjustments on the fly, which we could not do before.” MFView Glossary of Metalforming Terms

See also: Siemens Industry, Inc.

Technologies: Stamping Presses

Video

Video