Characteristics of a typical hydraulic press:

• Variable stroke length.

• Slide motion and position control throughout the stroke.

• Variable slide velocity, even within a single cycle of the press, typically configured as fast approach, slow press and fast return.

• Full working energy at any speed.

• Full press capacity at any point in the stroke.

• Adjustability of stroke length, slide motion and velocity, and working energy.

• Generally reduced throughput, accuracy and repeatability compared to a mechanical or servo press, with relatively low initial cost.

A mechanical servo press (flywheel, clutch and brake are replaced by high-capacity motors): offers much of the versatility of a hydraulic press at production speeds often approaching that of traditional mechanical presses. Stroke, slide motion and position, and speed are programmable to allow different combinations that can work with a variety of dies, part types and production speeds.

Characteristics of a mechanical servo press:

• Variable stroke profiles.

• Precise slide motion and position control throughout the range of the stroke.

• Variable, precise slide-velocity control, even within a single cycle of the press stroke.

• Full working energy at any speed.

• Programmability of all of the above-mentioned parameters.

• Full press capacity near stroke BDC.

• Generally greater cycle speeds than a hydraulic press, in many cases approaching the speed of a traditional mechanical press.

• Generally greater cycle speeds than a hydraulic press, in many cases approaching the speed of a traditional mechanical press.

• High accuracy and repeatability.

• Relatively high initial cost.

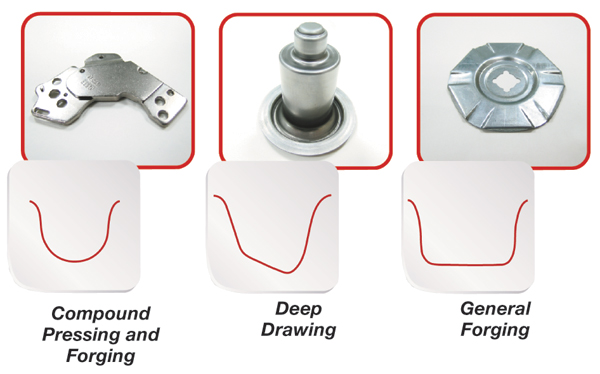

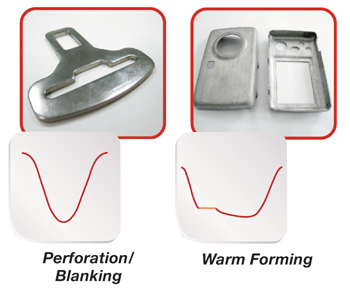

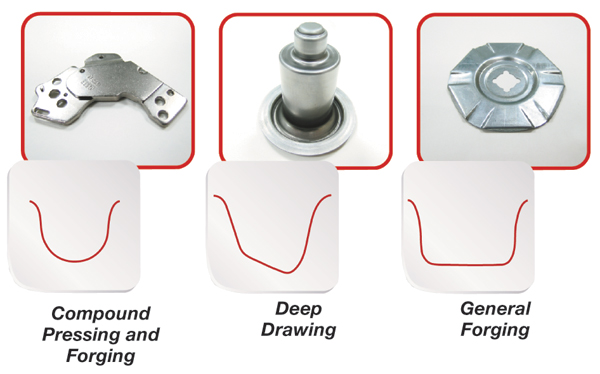

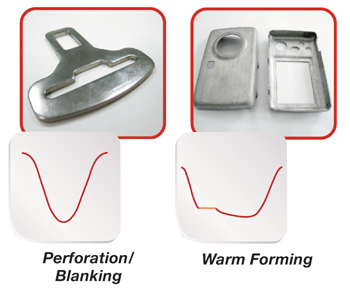

Shown are examples of stroke profiles and parts that can be achieved with a servo press.

Two Types of Servo-Drive Systems

Metalformers can select from two types of servo-press drive technologies. A link-assisted drive system provides a cost-effective solution that utilizes standard, off-the-shelf AC servo motors. A link or toggle mechanism coupled with the motors creates mechanical ratios that allow use of standard motor sizes from proven motor and control suppliers. No proprietary motors or motor controllers are required.

A direct-drive system employs proprietary, high-torque low-rpm motors specifically designed for press applications. These motors replace the standard motor, flywheel and clutch/brake in an otherwise traditional crankshaft-style mechanical press.

Regardless of drive type, servo presses will run from a proprietary control designed to allow for the wide variety of stroke and slide-movement profiles possible, while supplying full working energy even at low speeds. Unique profiles can be created by the user; each profile can include:

• Cycle

• Cycle

• Swing

• Multipass

• Simulation of link motion

• Compound pressing and forging

• Deep drawing and general forming

• Perforation/blanking

• Warm forming

With full working energy available at any speed and the ability to dwell anywhere in the stroke, servo presses are taking a big bite out of the drawn-and-formed parts pie. However, servos still are mechanical presses at heart, and achieve full tonnage capacity near the bottom of the stroke. So, hydraulic presses—with full tonnage and energy through-out the entire stroke—still offer an advantage in many applications. MF

Get more info at:

Stamtec, 4160 Hillsboro High, Manchester, TN 37355, Tel: 931/393-5050, www.stamtec.com

See also: Stamtec, Inc.

Technologies: Stamping Presses

Video

Video