Hybrid Robotic-Welding Gun Adds to Automation Benefits

October 1, 2012Comments

|

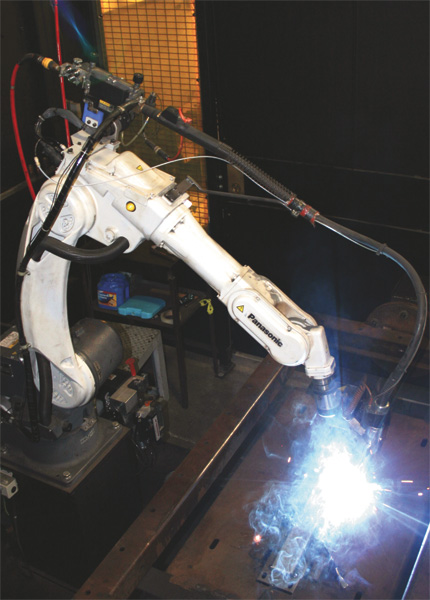

| One of the two robotic-welding cells operating at K-zell Metals—the company gained a full return on its automation investment within two years. |

Custom contract manufacturers must be prepared for any job that comes through the door—no matter how complex or challenging. Don Kammerzell, owner of K-zell Metals, Inc., Phoenix, AZ, knows that firsthand.

“We do the jobs that nobody else wants to do…or can’t,” Kammerzell says. “Everyone in the area knows that they can rely on us to work with almost any material and on almost any design.” Among the firm’s unique projects: fabricating horse-race starting gates, constructing limited-edition silicon-bronze playground sculptures and supplying components for military vehicles.

Robotic Welding a Competitive Advantage

In addition to custom-forming, laser-cutting and CNC press-brake equipment, K-zell Metals also operates a pair of robotic arc-welding cells that allow the company to create precise assemblies and maintain a competitive edge, compared to the days when it relied solely on semiautomatic arc welding.

According to Kammerzell, the robotic-welding cells have allowed the company to significantly increase throughput. It can produce as many as 5000 parts in a single run, while maintaining the same overhead.

K-zell outfitted each robotic-welding system with a hybrid air- and water-cooled robotic gas-metal-arc-welding (GMAW) gun, the Tregaskiss Tough Gun I.C.E (Integrated Cooling Enhancer). The hybrid design allows water circulation to the nozzle, keeping the front-end consumables running cooler and lasting longer. The design, says Kammerzell, allows K-zell Metals to easily switch from welding thick and thin parts without the hassle or downtime of changing out the entire gun.

Choosing the Right GMAW Gun

|

| The hybrid gas-metal-arc-welding gun combines the durability of an air-cooled gun with the cooling features of a water-cooled one. The external water lines circulate coolant to the front-end consumables, helping them run cooler and last longer when welding heavier gauge work. |

Given that K-zell welds on such a variety of parts, materials and thicknesses, Kammerzell, along with the company’s robotic-welding supervisor and quality-assurance manager Jim Benjamin, sought one robotic GMAW gun that could accommodate it all—the Tough Gun I.C.E. The hybrid gun features stainless-steel water lines that run along the outside of the gun’s gooseneck down to the nozzle, rather than through the gooseneck like traditional water-cooled guns. The design provides water circulation that keeps the consumables running cool, and it simplifies maintenance.

When welding thicker parts (1⁄4 in. or so), Benjamin explains, the weld-cell operator connects the I.C.E. gooseneck to an external water cooler within the cell. The addition of the water cooling allows the company to weld at the higher amperages required when welding thicker parts, or when welding for prolonged periods of time. When welding thinner parts (16 to 10 gauge typically), the operator changes over to an air-cooled gooseneck.

“I like the interchangeability of the air- and water-cooled necks,” says Benjamin. “It allows us to run a wide variety of applications on the same robot, with the same power source and in the same cell. Plus, the gun features a quick-change neck, so we can swap them out with minimal downtime.”

Benjamin also appreciates the safety and durability of the gun. “In the event of a crash,” he explains, “the gun’s safety features prevent it from becoming damaged.”

To both Benjamin and Kammerzell, having equipment that can keep up with the unique demands of their customer base is non-negotiable. “Being a job shop, we never know if we are going to have 10 parts, one part or several hundred,” Benjamin says. “Having a gun we can so easily swap out and maintain is a huge benefit.”

Investing in Automation

When Kammerzell and his team decided to invest in robotic welding, the goal was to gain a 15- to 20-percent increase in productivity and reduce costs—for its customers and for themselves. It’s exceeded those goals, while also focusing on delivering precise, repeatable parts to the welding cells.

“Having the robotic-welding cells has forced our laser and press-brake operations to be absolutely perfect, and they’re automatically checked every day,” Kammerzell explains. “Every part must be in spec in order to fit in the welding fixture—a built-in quality-control mechanism.”

The time, effort and labor needed to refine the company’s robotic-weld operations, and the fabricating processes that feed parts to the cells, have paid off handsomely. Kammerzell notes that the firm received a full return on its automation investment within two years. MF

See also: Tregaskiss, Miller Electric Mfg. Co.

Technologies: Welding and Joining