Stuart Keeler

Stuart KeelerCorrect Terminology Helps Troubleshooting

November 1, 2011Comments

Slang, jargon, ancient expressions, personal opinions and press-shop war stories are not beneficial when attempting to troubleshoot problems. Some terms may be meaningful to one person but cause another to completely misunderstand the problem. An analogy: Texting abbreviations that are well known to teenagers but appear to be a foreign language to others.

In the workplace, use of incorrect terminology can waste excessive and often critical time as employees try to uncover root causes, increase production speed or improve product quality. The following case studies highlight these problems.

1) “The steel stamping is beginning to strain.” A visually critical area of the stamping surface shows a series of narrow lines or depressions. If this area was just beginning to strain, Lüder’s lines or yield-point elongation in the incoming steel would be high on the probable-cause list. These Lüder’s lines initiate at very low strain. However, ultrasonic thickness measurements show high thinning in that area, indicating that Lüder’s lines are not a probable cause. The next step: Grid a stamping to allow measurement and plotting of the two surface strains (50 percent major and 35 percent minor) on the forming-limit diagram. The strains are on the edge of deformation cliff (zero safety margin). The surface markings are shear bands associated with the onset of the localized thickness neck—the precursor to failure. Some companies in Asia use surface-roughness measurements to detect these lines and use them as red flags highlighting incipient failure sites. Seeing these surface marks, one should have said, “The stamping is beginning to fail.” This requires completely different troubleshooting solutions.

2) “The dry lube we use does not provide the great benefits everyone talks about.” There are at least two vastly different dry lubes. The newer dry lube that can reduce the coefficient of friction by a factor of 4 (from 0.12 to 0.03) is a barrier lube. A coating (often a polymer) is applied to the sheetmetal surface and allowed to dry. This barrier separates the surface topographies (roughness) of the sheetmetal and the die, eliminating the friction caused by the surface asperities of the interacting surfaces. The coefficient of friction of the interface now is created by the laminar flow within the lubricant. The person with the complaint above actually was using vanishing oil. While a dry lube, the remaining residue does not perform as a dry barrier lube.

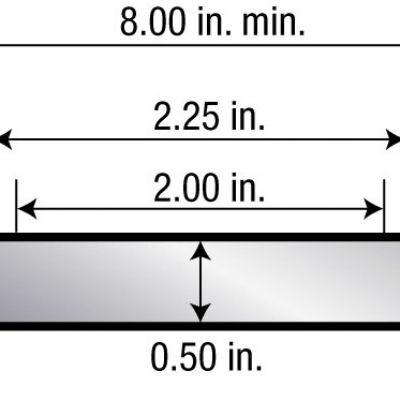

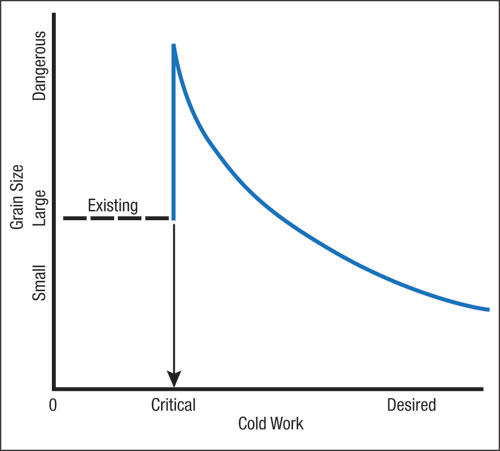

A critical amount of cold work can trigger formation of a few extremely large sheetmetal grains that cause early failure during forming.

3) “Some grades of the new advanced high-strength steels (AHSS) are so hard that we can only form them once, because they become brittle and fracture in the next die.” Calling these grades “hard” sends the wrong message. While hardness is an excellent measure of a material’s or die surface’s resistance to wear, it does not describe formability, strength does. Strength is a measure of resistance to deformation. While hardness generally increases as strength increases, the various mechanical properties controlling formability correlate to material strength. Some AHSS are designed to be more formable than HSLA steels of the same strength. Others have the same formability as HSLA steels but at a higher strength. Forming any steel creates work hardening that further increases its strength. Within formability limits, the sheet steel still can undergo additional forming. However, a greater force is required to generate the next forming operation. This higher force often causes increased deformation in other areas of the stamping and not at the desired location. Eventually the useful formability is exhausted and the stamping undergoes local necking and fracture. However, when these steels fail, the failure mode is still ductile, not brittle.

Video

Video