The firm built its inventory warehouse in 2006, in part to de-clutter its fabrication shops and clear aisle space for forklift traffic. “The inventory that was spread all over our shops also became difficult to manage and track,” says Baxley. “Now the warehouse shelves are clearly labeled and organized and material is easy to locate.”

More Nozzles Allows for Custom Setups

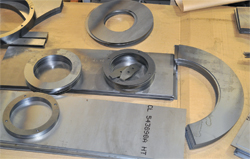

Back in the blowpipe shop, as the laser finishes its work on the 12-gauge stainless-steel sheet, an operator loads a completely different job on the second of the cutting machine’s two pallets. Since firing up its new laser-cutting machine in October 2009, the plant has processed 93,000 sq. ft. of sheet, 35,000 sq. ft. of which required laser cutting.

“On a daily basis, we might go through 10 or more different setups on the machine, whether it is for a change in material type or thickness,” says Baxley. “And here is where the new technology offered with the new machine really pays off. The machine can automatically change its torch, lens, nozzle and beam mode so it als uses the ideal setup for every application.”

Changeover of a typical laser-cutting machine can take several minutes, and as long as an hour if you’re customizing the entire setup for each material type and thickness. While Baxley did not do that with its older machine, its use of only two nozzles to cover its entire range of material type and thickness proved less than ideal.

Conversely, Baxley’s new Hyper Turbo-X 510 features an automatic nozzle changer and is equipped with six different nozzles (1.2 mm, 1.5 mm, 2.0 mm, 3.0 mm, 3.0 mm double and 2.0 mm double), as well as two lenses (5 and 7 in.). So not only is the machine cutting more quickly than before, the company spends much less time performing changeovers.

The nozzle changer represents one point in what Mazak calls its AO5 Point Setup: nozzle spatter removal, nozzle changeover, focal-point inspection and automatic lens replacement, nozzle inspection and replacement, and torch changer.

“Before, the operator als had a sheet or two waiting to be cut,” says Baxley. “Now he’s often waiting for material. The new machine has created excess machine time, which we’ve been able to leverage to improve our maintenance procedures. The operator now has more time to spend cleaning the nozzles, lenses, etc., which has improved our cut quality in some instances.”

Baxley notes that the goal is to clean the lenses after every 40 hr. of cutting time at a minimum for processing carbon steel, and after every 20 to 25 hr. of cutting time when processing stainless steel or aluminum.

Gas Savings Galore

Lastly, Baxley points out that he’s noticed a substantial reduction in cutting-gas consumption since installing the new cutting machine and taking full advantage of its array of nozzles. The shop uses nitrogen assist gas when cutting stainless steel, aluminum and galvanized, and oxygen to cut carbon steel.

“We used to order three 200-liter tanks of liquid oxygen per month and now we’re averaging just less than one full tank per month,” shares Baxley. “And, our liquid-nitrogen consumption has dropped from as many as 20 200-liter tanks per month down to just 12 per month. All told we’re saving as much as $1000/month just in gas consumption.” MF

View Glossary of Metalforming Terms

See also: Mazak Optonics Corporation

Technologies: Cutting