Can Alloys Exhibit Superplastic Forming?

February 1, 2009Comments

A year or two ago, print media praised the forming of a very complex automotive trunk lid with only a single die. The secret ingredient was a superplastic aluminum that stretched into very sharp features without necking or other failure modes. The aluminum stretched to strain levels beyond any other material. Much superplastic forming research is not new but occurred during the 1960s at the Massachusetts Institute of Technology. Two laboratory demonstrations showed the fascinating capabilities of this very special aluminum alloy. In one demonstration, a standard round tensile test specimen (0.505-in. dia.) reached total elongations ranging from 2000 to 3000 percent before failure. In some tests, the specimen approached the diameter of a human hair without failure.

The other demonstration began with a box having 1-ft. square sides. The box contained one of the old spherical typewriter balls set in the center of the bottom of the box. This ball had raised letters and numbers around the surface. In the typewriter, the ball rotated to imprint each letter or number into the inked tape. The forming process began with clamping the sheet of superplastic aluminum over the top of the box to ensure a tight air seal. Then a vacuum pump removed the air from the sealed box. The aluminum sheet gradually sank into the box and took the shape of the inside of the box by forming all inside zero-radius edges and corners of the box. In the process, the aluminum sheet also wrapped itself around the type ball and embossed every letter and number through the sheet to create a duplicate of the original ball. Those two demonstrations made complete believers of everyone who witnessed the tests.

Why didn’t the capability of this alloy

|

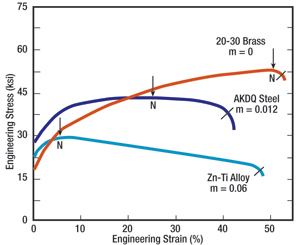

| Three stress-strain curves illustrate the increase in strain after the onset of a diffuse (width) neck, marked by downward arrow plus N. This additional strain is proportional to the m-value. |

Once a new material capability is discovered, product designers immediately want to incorporate the new features into future part designs. Potential application by a huge industry (such as automotive) provides the driving force for additional research to further focus the material characteristics to end-user needs. In this case, elongations of 2000 to 3000 percent are far greater than target parts required. Therefore, metallurgists tweaked the chemistry and processing to reduce cost. New microstructures allowed an increase in forming speed. Ultimately, the total part cost equaled the value of the benefit received and the process went into production.

One fundamental measure of superplastic behavior is the strain-rate hardening exponent or m-value.

Video

Video