Laser-Weld Inspection for Safety-Critical Welds

April 1, 2008Comments

Automotive OEMs and suppliers, along with other

|

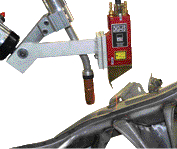

To provide automated weld inspection, the laser camera scans the weld profile for visible discontinuities such as voids, convexity, and undersized or undercut conditions. The laser sensor is flexible, and the user can set accept, warn and reject limits on discontinuities. Output from the sensor can be used to separate nonconforming parts from production.

For Six Sigma production, the camera supplements arc monitoring by verifying that welds look good and are in the proper location. The laser camera provides quantifiable inspection results, and nonconforming parts are separated from production, reducing the need to use third-party containment.

Using laser-weld inspection as part of the manufacturing process keeps poor-quality or missing welds from being covered with additional brackets or other components. Laser cameras can be used to inspect the final weldment to detect nonconforming parts prior to assembly.

Motoman: 937/847-6200; www.motoman.com

See also: Yaskawa America, Inc.

Technologies: Quality Control, Welding and Joining

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsEngineered Solutions is the Name of the Game

Brad Kuvin Thursday, February 8, 2024

Welding and Joining

Welding and JoiningWhy Are There Black Spots on My Aluminum Welds?

Robert Cohen Monday, September 25, 2023

Welding and Joining

Welding and JoiningWeld Systems Integrators Hires Ed Turner as Southeast Region...

Thursday, August 3, 2023