Pneumatic Press Supports Progressive-Die Work

November 1, 2008Comments

Airam Press Co. Ltd., Covington, OH, has introduced the PulsAir a pneumatic press developed to support

|

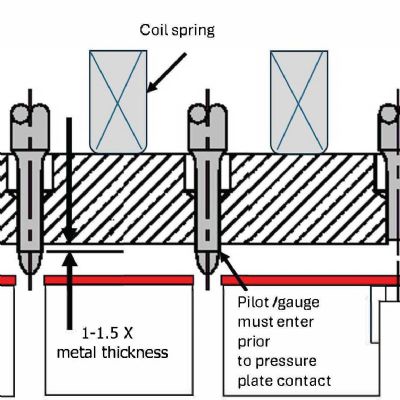

Long-length precision guiding provides manufacturers with the ability to run progressive dies while minimizing the effects caused by off-center loading—features that ensure part accuracy. Stroke length is adjustable in increments as small as 0.004 in. Since the press ram can dwell on the top or bottom of the stroke, manufacturers can match or exceed press speeds for a production line or stamping job to achieve greater productivity. New available features are inching or job control for the ram, and remote ram-speed adjustment.

The PulsAir’s small footprint simplifies installation. With few moving parts, maintenance is minimal and only a small amount of lubrication is required. The press is available in gap and straightside models from 7 to 200 tons. Airam can custom design press applications with minimal engineering costs.

Airam Press Co. Ltd.: 937/473-5672; www.airam.com

See also: Airam Press Co. Ltd.

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Tooling

ToolingAvoiding the 7 Deadly Sins of Stamping: Part 2—Out-of-Sequen...

Art Hedrick Friday, March 29, 2024

Stamping Presses

Stamping PressesIncreasing Press Speed and (In)Efficiency

Peter Ulintz Thursday, March 30, 2023