Best Practices for Preventing Hearing Loss

October 1, 2008Comments

Unlike hitting your thumb, falling or being burned, noise-induced hearing loss (NIHL) is accompanied by no visible trauma. It happens slowly over time and may not even be noticed for years. Nonetheless, NIHL is permanent and irreversible.

Prevent hearing lossHowever, NIHL is 100 percent preventable. OSHA’s Occupational Noise Standard (CFR 29 1910.95) mandates a number of specific measures to help prevent NIHL (and resulting compensation claims) in the workplace.

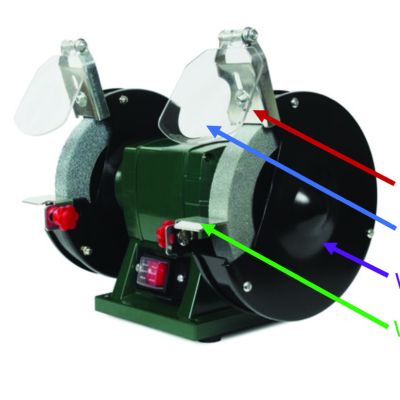

Draw a noise map. OSHA requires “monitoring” to help make noise “visible.” In addition to noise area monitoring, use a dosimeter to measure actual employee exposure and communicate the results. Instead of small Hearing Protection Required or Noise Hazard Area signs, shops should post noise maps of the area or facility in common areas, such as the locker room or cafeteria. Another option is to post decibel levels directly on equipment so employees can see their exposure levels while they work. Placing motivational posters and noise thermometers on bulletin boards and in common areas also can help educate employees about noise hazards and keep the need for protection uppermost in their minds.

Train individuals, not just a group. Group training

|

sessions and seminars should include information on the effects of noise exposure; the selection, use and proper fit of hearing-protective devices (HPDs); and the procedures for audiometric testing.

Studies show that individual, one-on-one sessions prove more effective in teaching workers how to properly fit and wear HPDs. Including a record of an employee’s noise exposure in a personnel file can help an audiologist better understand the worker’s history when interpreting new audiograms, and few things get employees’ attention faster than seeing dips in their charts. A review of proper fit procedures now make it possible to assess fit effectiveness using the worker’s own earplugs.

Offer a choice in HPDs, not just variety. OSHA requires that “a variety” of hearing-protective devices—earplugs and/or earmuffs—be made available at no cost to workers exposed to an 8-hr. TWA (time-weighted average) of 85 dB (85 dBA). But OSHA does not specify what constitutes “a variety,” and people’s ears are different. One earplug or earmuff style is unlikely to be suitable for all applications or even comfortable for the entire workforce. And comfort is the number one driver in HPD usage.

It’s a good idea, then, to offer choices, including different materials and styles designed for specific applications and/or worker preferences. These range from dielectric and cap-mounted earmuffs to “smart fitting” earplugs that conform to the shape of the user’s ear canal, multiple- and single-use earplugs, as well as banded earplugs that can quickly be inserted during intermittent noise. Earmuffs, too, come in a range of configurations.

Sperian Hearing Protection: 800/430-5490; www.howardleight.com

See also: Sperian Hearing Protection, LLC

Technologies: Safety

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Safety

SafetyPilz Digital Maintenance-Safeguarding System an Efficient Al...

Thursday, March 16, 2023

Safety

SafetyNew from Pilz: Machinery Safety Evaluations

Tuesday, February 14, 2023