Peter Ulintz

Peter UlintzAluminum Lightweighting Challenges

March 1, 2013Comments

Lightweighting has become a common term in the automotive industry. It describes product-design activity that maximizes fuel efficiency to meet federal corporate-average fuel-economy (CAFE) requirements through the reduction of vehicle mass. Currently, this is being achieved through the use of higher-tensile-strength steels, allowing automakers to reduce the thickness of metal stampings.

Last month we examined how high-strength steel can push press-line performance requirements well beyond the capabilities and limitations for which they were originally designed. But manufacturing challenges associated with lightweight stampings are not limited to high-strength steel; applications for aluminum stampings are growing in automotive applications.

|

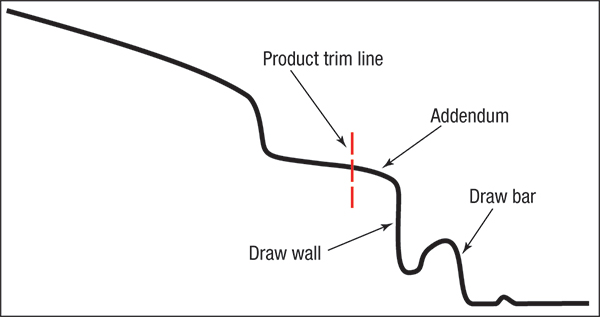

| Addendum features are added on beyond the product trim line. |

Immediately after exposure to air, aluminum forms a thin natural layer of aluminum oxide on the sheet surface that can break down during forming and abrade the tooling. This often requires an application of PVD, TD or other surface treatments to protect the tooling. A light overall lubrication should als be applied to both sides of the blank, even during blanking and shearing.

Aluminum also has one-third the elastic modulus of steel. This reduction in Young’s modulus increases the magnitude of springback by a factor of three compared to steel sheet of equivalent thickness and yield strength. The reduced elastic modulus also increases the likelihood of surface distortion such as wrinkling and oil canning. The ultimate aluminum stamping stretches evenly and distributes strains uniformly when deformed.

Deep Drawing

Proper blank size is particularly important when deep drawing aluminum. A rectangular blank, often selected for simplicity and low cost, does not necessarily maximize formability. Designers optimize blank shapes through analytical methods (forming simulations) or by trial and error. Regardless of the method chosen, developed blanks will vastly improve aluminum draw-forming processes.

Difficult and irregularly shaped product geometries often require the use of an addendum to improve material flow in the die. Common addendum features include draw walls, draw bars, material gainers, take-up beads, pillows and punch extensions. Designers add these features beyond the product trim line (see figure) to assist material flow by balancing cross-sectional lengths of line and providing a constant depth of draw.

The deformed surface area resulting from the first draw operation must be equal to the total surface area in the final draw. Excess surface area can cause oil canning, buckling and wrinkling. And, if the surface area in the first draw is less than that in the final draw, tensile failures may result due to stretching.

Draw-reduction ratios for cupping will vary depending on the aluminum grade being formed. Some grades of aluminum can have limiting draw ratios (LDR) similar to those of steel, while others are much lower. Many die-design handbooks contain draw-reduction tables for low-carbon steel. Do not use these tables for brass, aluminum or any other nonferrous materials, due to differences in work-hardening behavior, surface topography and other factors.

For aluminum alloys, keep the LDR below 1.6 (unless you have previous experience with the particular alloy being stamped), which is equivalent to approximately a 38-percent reduction for the first draw. Shoot for reductions of approximately 22 percent, 17 percent and 12 percent in subsequent redraw operations, providing the ratio of material thickness to blank diameter (t/D x 100) is 0.25 or greater.

Keeping friction to a minimum, while controlling material flow, is the key to successful deep drawing. Excessive blankholder pressure forces the aluminum to stretch. Use just enough pressure to keep the aluminum sheet from wrinkling, and use standoffs to control the gap between the die face and the blankholder surface.

Use a lubricant designed for drawing and forming of aluminum. Lubricants that work well for steel sheet most likely will not work well for aluminum. Don’t guess—contact a lubricant specialist.

Product Design Guidelines

Specify part radii carefully. Small radii will localize strains and promote stretching, and the part may fail quickly, while large radii will reduce the contact area between the blankholder and the part flange. This increases the tendency to form wrinkles in the area near the die radius.

Generally, specify punch radii for aluminum stampings between eight and 10 times material thickness, and die-entry radius between five and 10 times material thickness. Whenever possible, keep punch radius larger than die radius to reduce the tendency for the punch to penetrate through the material. MFView Glossary of Metalforming Terms

Technologies: Materials