Software Release Streamlines Digital Planning and Validation of Sheetmetal Processes and Parts

November 1, 2013Comments

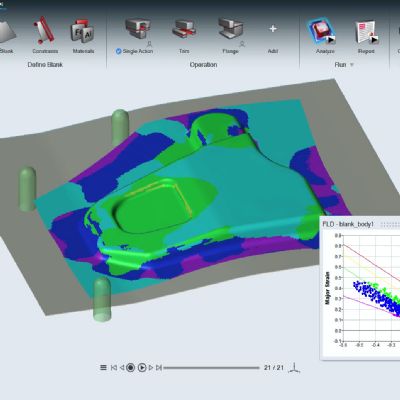

AutoForm Engineering GmbH (U.S. headquarters in Troy, MI) has introduced its latest software version, Auto-Formplus R5, providing a host of new features and improvements for digital planning and validation of sheetmetal processes and parts. Besides new planning options and tooling features, this release offers several new avenues to improve the efficiency and reliability of result evaluation.

AutoForm Engineering GmbH (U.S. headquarters in Troy, MI) has introduced its latest software version, Auto-Formplus R5, providing a host of new features and improvements for digital planning and validation of sheetmetal processes and parts. Besides new planning options and tooling features, this release offers several new avenues to improve the efficiency and reliability of result evaluation.

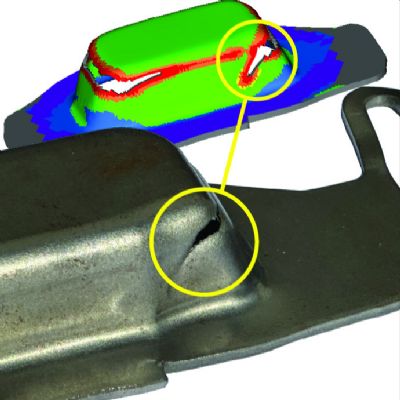

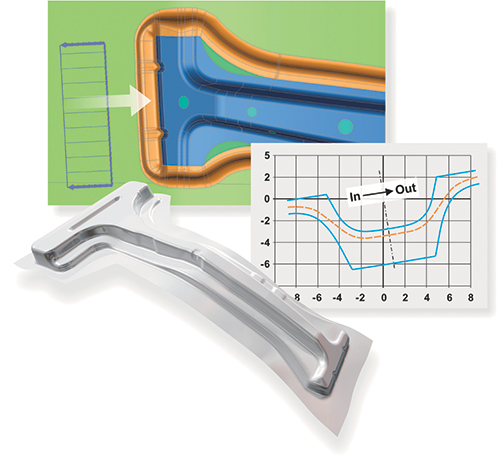

For example, new section plots allow for results to be charted along selected geometry sections. A newly developed issue type for semiautomatic result evaluation allows the user to track the draw-in location and its progression. And, the digital stoning analysis has been enhanced to simplify and make more accurate the evaluation and visualization of surface imperfections.

Solver improvements have been included as well, to increase result accuracy and shorten computation time. An improved contact algorithm leads to more realistic bending behavior in wall and flanging areas, results in a more precise calculation of tool forces, and a creates a very realistic representation of wrinkles in the binder area.

With AutoFormplus R5, users can more readily evaluate the design parameters that most-influence part quality, and to what extent—with conventional and hot-forming processes. Engineers can identify the design parameters that have the most influence on the stamped part, during the process- and part-design stages. They then can make the necessary adjustments and systematically improve the forming process by specifying sophisticated quality criteria such as surface defects and draw-in issues.

AutoForm: 888/428-8636; www.autoform.com

See also: Autoform Engineering USA

Technologies: Software