Brad Kuvin

Brad KuvinWaterjet Cutting Keeps the Work Flowing

August 1, 2012Comments

|

| Tru-Fab owner John Stegh works on a plate nest at the machine control tending to the firm’s Omax bridge-style 80X series JetMachining Center, with x-y travel to 165 by 80 in. |

Nine times out of 10 I can tell the company owner apart from the machine operators. Okay, 99 percent of the time. Little did I know that when John Stegh greeted me at the door of Tru-Fab Technology, Inc. a few weeks back, dressed in shop overalls and ball cap, that he not only was a machine operator (a highly skilled welder, as well as a programmer and operator of the firm’s laser- and waterjet-cutting machines), but also the company’s founder and president.

Tru-Fab’s 75,000 sq. ft. of manufacturing space, spread over four buildings in Eastlake, OH, bears absolutely no resemblance to its humble beginnings as a welding shop born in Stegh’s garage in 1995. But just one year after he set up shop, to work on side jobs, Stegh had earned enough customers to move into a 1750-sq.-ft. facility. On the fast track to growth, the company moved to a 15,000-sq.-ft. shop in 1999. By 2004 when the firm relocated to its current home, Stegh had expanded well beyond welding into full-blown sheetmetal fabrication, including laser cutting; his latest investment is a 4000-W laser-cutting machine acquired in 2011. It’s no wonder Tru-Fab has appeared consistently on the Weatherhead 100 list of Northeast Ohio’s fastest-growing companies.

|

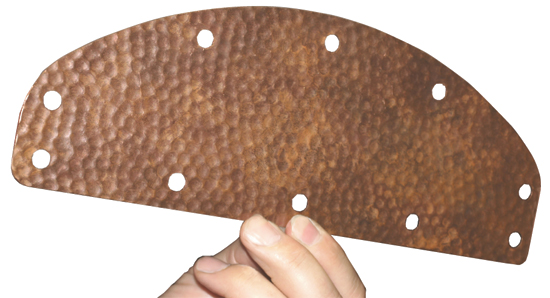

| Stegh counts on his waterjet-cutting machines to satisfy customers looking for fabricated components from reflective alloys, such as this motorcycle foot pedal fabricated from heavily dimpled 0.045-in.-thick copper-alloy sheet. “Our lasers could never have cut this material, and would have struggled to pierce all of the holes, but waterjet cutting worked like a charm,” he says. |

“As the business grew, so did the variety of opportunities we received from customers to take on different types of work,” says Stegh, reflecting on the company’s rapid evolutionary pace along with his determination to learn and grow to meet the twists and turns of his customers’ needs.

“Before we were able to diversify and offer the variety of capabilities that we can offer now, we tried outsourcing some work,” recalls Stegh, referring to some of the unique processes his firm offers, such as deep-hole drilling and screen printing. “But some suppliers simply let us down in terms of meeting delivery dates and quality requirements. That’s as good an explanation as any as to why I have acquired as much varied equipment as I have over the years.”

Waterjet Capabilities are “Endless”

|

| Stegh particularly appreciates the Tilt-A-Jet accessory cutting head, designed to achieve a nearly zero taper. He has it installed on his Model 55100 machine. The cutting head positions the nozzle at an angle determined by the Omax Intelli-Max software—based on material type and thickness, and cutting speed—to compensate for predicted taper. This moves the tapered edge to the scrap rather than the workpiece. |

Stegh describes his company as a “metal-fabrication shop with the ability to do a lot more,” a mantra that has proven itself over and over as he has grown the shop’s capabilities. That growth includes the acquisition of two waterjet-cutting machines, both from Omax Corp., Kent, WA. In 2008 it brought in a cantilever-style Model 55100 Jet-Machining Center, with workpiece capacity to 55 by 100 in. In 2010, Stegh upsized to Omax’s bridge-style 80X series JetMachining Center, with x-y travel to 165 by 80 in. Features include linear drives and a programmable motorized z-axis. With the machines at or near capacity, Stegh seems likely to purchase a third waterjet machine by the end of 2012.

“The capabilities of those Omax machines are endless,” Stegh says, “and often we can achieve better edge quality than we can with our lasers. We’ve cut stainless steel to 3 in.; capacity on our lasers is ½ in.”

In addition to metal-alloy work, Stegh also waterjet-cuts nonmetals such as rubber and plastic. But he points out in particular how well the process performs on reflective alloys—copper and aluminum—where his laser-cutting machines struggle. For example, a customer that modifies motorcycles recently came to Tru-Fab in need of copper-alloy foot-pedal covers, fabricated from heavily dimpled 0.045-in.-thick sheet, and containing several small-diameter holes.

“The lasers could never have cut that material, and really would have struggled to pierce all of the holes, but waterjet cutting worked like a charm,” Stegh says. Tru-Fab fabricated more than 500 of those parts, once again proving that process flexibility is a critical component to consistently satisfying customers.

|

| Tru-Fab waterjet-cuts parts from 3⁄8-in.-thick steel plate to fabricate these assemblies used in electrostatic precipitators. |

“In fact, being able to turn those motorcycle foot-pedal covers very quickly led that same customer to contract us for a lot more work, including laser cutting of stainless-steel speaker covers,” adds Stegh. “We’ve made thousands of those.”

Tru-Fab boasts some 100 active customers to which it ships parts at least monthly; most reside within a 150-mile radius of the company’s Cleveland-area home base. Key end-user industries include material-handling equipment (conveyors, forklifts, etc.), medical, power generation and aerospace. It takes in orders nearly every day with part volumes of one or two to a few hundred. Head count ranges from 35 to 40, although Stegh can see that expanding to 45 within the next couple of years, noting that the firm has hired two new employees so far this year.

Programming at the Machines

While Stegh and a few others will occasionally program the waterjet-cutting machines offline, much of the jobs are programmed at the machine controller. Each machine control includes software add-ons to enable program creation and modification, particularly useful when customers come with one-off orders requiring quick turnaround.

One Omax feature Stegh particularly appreciates is its Tilt-A-Jet accessory cutting head, designed to achieve a nearly zero taper. He has it installed on the Model 55100.

“While aluminum cuts fairly straight and often does not require compensation,” he says, “steel can taper quite a bit.” Taper occurs because the energy of the waterjet is greater at the top of the cut than at the bottom, resulting in a wider kerf at the top. In some cases, fabricators can experience reverse taper. Here the waterjet removes more material from the bottom of the cut than from the top; the phenomenon can occur during very slow cuts or when working with very soft materials.

|

| Stegh pointed out this plate skeleton to highlight the edge straightness and quality achieved with waterjet cutting. Shown is 2-in.-thick type 4140 mild steel. “This is wire-EDM-like quality,” he says, “with top-to-bottom straightness within 0.020 in.” |

The Tilt-A-Jet cutting head positions the nozzle at an angle determined by the Omax Intelli-Max software—based on material type and thickness, and cutting speed—to compensate for the predicted taper. This moves the tapered edge to the scrap rather than the workpiece. The head offers programmable tilt to ± 9 deg., as well as 6 in. of vertical travel.

“The parts come off perfectly square with taper-free edges,” says Stegh, “without having to reduce cutting speed—the alternative method to reduce taper. We’re achieving taper as little as 0.003 in. top to bottom on 1-in. steel plate. That’s unheard of, on par with wire-EDM.”

In addition to software support for taper compensation, Stegh also appreciates the software’s ability to control cutting-stream pressure to allow piercing of brittle materials. “That feature has allowed us to pierce and cut ceramic tile and glass,” Stegh adds.

The ability to quickly produce straight-walled precision cuts allows Stegh to process some work that might otherwise require CNC machining—a slower and more costly option. “And, we can waterjet-cut very small holes in thick plate that we’d otherwise have to machine,” he says. “For example, we just processed a part from 3⁄4-in. mild steel that required waterjet cutting of 0.312-in.-dia. holes. Can’t do that on a laser, and it’s much more cost effective than CNC machining.” MFView Glossary of Metalforming Terms

See also: Omax Corporation

Technologies: Cutting, Fabrication

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingNew Line of Wear-Resistant Waterjet Nozzles

Friday, February 24, 2023