Software Facilitates Systematic Tryout Rather than Trial and Error

November 1, 2010Comments

The fine tuning of a forming tool during tryout is a cost- and time-intensive step on the path to a functioning tool. Correction work and modifications are inevitable, and every correction loop that can be eliminated offers an immediate advantage in terms of time and money. To do so requires a systematic approach not confined to the boundaries of individual operational departments.

The fine tuning of a forming tool during tryout is a cost- and time-intensive step on the path to a functioning tool. Correction work and modifications are inevitable, and every correction loop that can be eliminated offers an immediate advantage in terms of time and money. To do so requires a systematic approach not confined to the boundaries of individual operational departments.

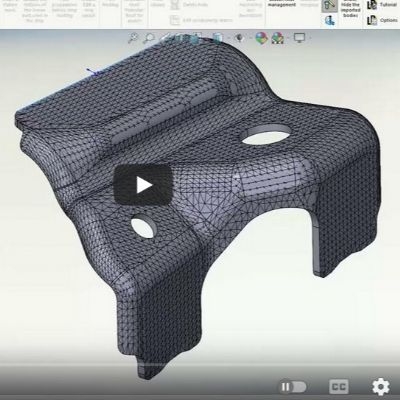

Engineering and tryout are separate operational departments in the tool shop. When the release for milling of a tool is issued, engineering generally turns its focus to new projects as the tryout team goes to work. For an effective tryout, both operational departments must bundle activities together—with the engineering department applying simulation-based tryout support occurring parallel to tool manufacturing. Should a problem arise in tryout, the cause can be identified on the computer.

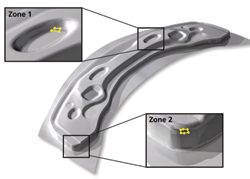

Should a problem arise in tryout, engineering refers to previously calculated simulation results (in AutoForm-Sigma). The software helps to determine suitable correction measures to allow development of an action plan. Should the tryout team identify, for example, two problem areas, such as a tear in the base of an embossment and a 23-percent thinned spot in the wall of a stamping that has a maximum stretch tolerance of 20 percent, engineering can examine these two areas more closely in simulation.

AutoForm-Sigma, from AutoForm Engineering, leads the user in logical steps through the analysis, showing the engineer which correction measures have no effect and which offer a real chance of resolving a particular problem. They also can check to see if the application of a correction measure, designed to resolve one problem, might actually create a new problem. By means of sliders, AutoForm-Sigma can progressively adjust the strength of each of the individual correction measures and simultaneously follow the effects on the entire part.

AutoForm Engineering: 888/428 8636; www.autoform.com

See also: Autoform Engineering USA

Technologies: Software

Webinar

Webinar