Time for an Upgrade

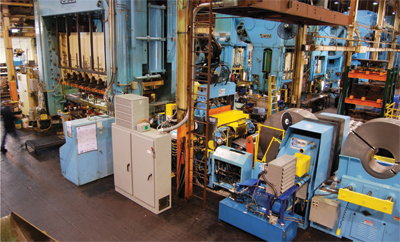

In 2006, Nieberding took on the challenge of finding a new feed and straightener system for the massive Verson press that could tackle the heavy-duty work load and deliver feed performance, straightening quality and simple serviceability. He began his search with a list of 11 press-feed suppliers he thought would be capable of satisfying Stamco’s specifications.

“The new system had to integrate with an existing coil-shuttle car,” says Nieberding. “There is no overhead crane where this press is located, so we use a traveling coil car to transport material 40 ft. from

|

Stamco’s new Dallas coil line features a hydraulically operated de-kinking mechanism to remove the trailing-end wrap bend of the coil ID, allowing Stamco to optimize material use. It also eliminates the need to manually cut the ends, and the associated risks. A coil stop, peeler and threading-assist assembly also are incorporated into the dekinking mechanism.

A single, 125-hp motor drives all of the equipment, and a chain drive connects to the cradle’s nest rollers to power the cluster-gear-driven straightening rolls, along with the feed rolls. The one drive motor ultimately synchronizes the entire system—there’s no need for material payout loops, which helps to minimize system length. The cradle-straightener can handle 30,000-lb. coils, 10 to 36 in. wide, to 72-in. OD. Maximum stock thickness is 3⁄8 in. for 80,000-psi steel. At a 12-in. feed length and 240-deg. press-feed cycle, the unit can support press speeds to 25 strokes/min. The feeder-straightener unit attaches to the main cradle base and includes a ±5-in. motorized passline-height adjustment, motorized adjustment of the straightening rolls, automatic lubrication and memory for storing job-setup parameter. The straightener incorporates nine 5.5-in.-dia. hardened and ground rolls, mounted using anti-friction bearings. The servo-controlled feed rolls are 8-in. dia. and hardened, ground and with a matte-chrome finish for prolonged life. The drive motor is a variable-speed AC vector-type system that allows smooth transitions in feed lengths from 0 to 99.999 in. in 0.001-in. increments. A remote forward-reverse jog pendant aides in threading new coils during changeovers.

|

storage area to loading point. So, we needed a coil cradle rather than a reel for the feed system, and some feed suppliers do not offer cradles. Then, when we refined the search to feed systems that could handle coiled material to 3⁄8 in. thick and 36 in. wide, the field of suppliers narrowed further.”

With four suppliers left in the hunt, Nieberding and his team visited existing, comparable system installations, and from these reviews they cut the prospect list to two suppliers. Stamco management made the final decision, along with an engineering and production panel, based on accumulated criteria presented by Nieberding’s team. The winner: a combination cradle-straightener-feeder from Dallas Industries, Troy, MI, installed at Stamco early in 2008.

“Factors that led to the decision included serviceability features we requested be included in the design, based on our previous experiences. These features include easy access to components, including guarded-drive linkages outside the main framework, as well as cartridge-style roller-bearing inserts that simplify bearing replacement,” Nieberding notes. “Now, a bearing changeover, even a roller changeout, takes only a day or less, not the week of downtime we used to experience.

“Also, the length of the new line requires only 17.5 ft. of floor space as compared to nearly 23 ft. for comparable units from other suppliers,” he continues. “With limited space restrictions and accounting for the path of the coil-shuttle car, this was critical.”

The cradle’s powered side guides and integral antifriction roller bearings allow Stamco technicians to adjust the guides by as much as 2 in. in either side-to-side direction. This action permits compensation for most conditions of coil camber and helps align the material to the centerlines of the straightener and feed units. Previously, Stamco could not thread coils received with excessive camber into the existing feed line, and therefore the firm had to reject as much as five percent of incoming coils, creating downtime as stock needed to be rewound, rebanded and a fork truck sent in to remove the coil from the cradle.

The new unit also features an automatic pilot-pin release mode, allowing precision die-actuated positioning of stock. The release operation raises the entire bank of straightening rolls and pinch rolls plus feed rolls, removing tension on the stock so that the material is free to move via location pins in the tooling. Then, too, the straightener head is returned into its normal operating position after the release cycle utilizing as much as 1500 lb. of hydraulic pressure to assure repeatable, accurate straightening performance. The release operation also aides in initial threading procedures of a new coil’s leading edge.

“That said, we’ve been able to run some jobs without the use of the die locating pins,” Nieberding adds, since the feed line provides the feed-length accuracy required for the job.

Bottleneck Relief

Brings Capacity Increase

Now that its feeder is more reliable, it’s no longer the bottleneck for the press line. In fact, Stamco expects to be able to increase the press’ stroke rate by as much as 10 percent, confident that the feeder will keep up.

“We’re a more reliable supplier because we have more reliable equipment,” says Stamco sales manager Doug Tisch. Increased press speed combined with less downtime for coil-line maintenance has opened up some 15 percent more capacity on the Verson press, “so that we can actively seek new business without having to make another capital outlay for a new press,” adds Tisch. MF

Information provided by Dallas Industries, Inc., Troy, MI: 248/583-9400.

Industry-Related Terms: Transfer,

Run,

Stroke,

Thickness,

Camber,

Die,

Edge,

Feed Unit,

Forming,

Piercing,

Plate,

Point,

RamView Glossary of Metalforming Terms

See also: Stamco Industries, Inc., Dallas Industries

Technologies: Coil and Sheet Handling, Materials, Stamping Presses