Robotic-Welding System with Dual-Work-Zone Turntable

November 1, 2008Comments

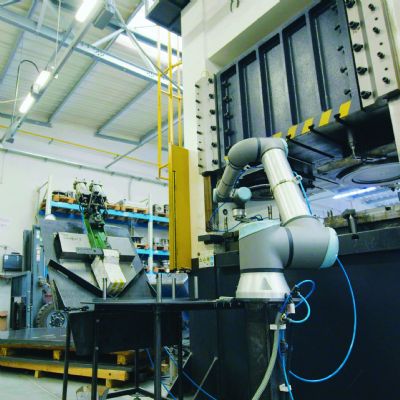

Lincoln Electric Co., Cleveland, OH, has debuted the System 20 robotic-welding system with a dual-work-zone turntable. It is ideal for users with small- to medium-sized parts that do not require positioning. The system includes a Lincoln Electric Power Wave i400 and AutoDrive 4R90 robotic system coupled with a

Fanuc ArcMate 100iC six-axis robot arm. The system features servo-driven positioners that are nearly maintenance-free—no mechanical components to fail such as cylinders, brakes, controls, etc.

System 20 offers a 58-in. dual-zone work system that can handle 600 lb. per side, with an index time of only 2 sec., delivered by the Fanuc-driven servo positioner.

The modular design can start off as a two-sided system and be modified later to become three- or four-sided for small part profiles. With a small footprint designed to optimize floor space, its steel skid structure is equipped with fork pockets for simple placement anywhere on the shop floor.

The cell comes equipped with features designed to improve the work environment. The control panel delivers push-button controls for ease of operation and large roll-a side doors for simple programming. PC board safety controls and integrated operator safety devices provide additional protection.

Value-added features include storage drawers for tips, nozzles and small tools, as well as work surface cut-outs to accommodate fixture utilities.

Lincoln Electric Co.: 216/481-8100; www.lincolnelectric.com

See also: Lincoln Electric Co.

Technologies: Pressroom Automation, Welding and Joining

Video

Video